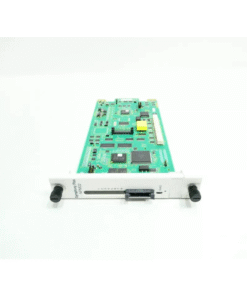

VALMET Positioner ND9106HNT – Advanced Control Performance Overview

The VALMET ND9106HNT positioner offers a highly reliable and intelligent valve control solution that fits a wide range of industrial applications. Because process environments continue to demand smoother operation, tighter accuracy, and stronger diagnostics, the VALMET ND9106HNT brings a refined design that supports stable performance even under challenging conditions. Moreover, the device integrates advanced monitoring functions, so operators gain real-time insight while maintaining continuous efficiency. As a result, users experience stronger process consistency and significantly reduced maintenance time.

1. Core Design and Structural Features

The VALMET ND9106HNT features a compact and rugged enclosure that protects internal components from vibration, dust, and moisture. In addition, the housing allows flexible installation on single-acting or double-acting actuators, so plants can standardize positioners across multiple control loops. The mechanical assembly uses industrial-grade materials, therefore ensuring long-term durability in chemical, oil & gas, power generation, and pulp & paper facilities.

Furthermore, the VALMET ND9106HNT supports direct mounting according to standardized interfaces. This compatibility helps technicians simplify setup procedures, because the positioner fits popular valve models without complex brackets. Its streamlined mechanical layout also allows fast calibration, and technicians can perform adjustments through intuitive local controls.

2. Control Performance and Operating Specifications

The VALMET ND9106HNT delivers highly responsive positioning, and the control algorithm ensures a smooth output across the entire stroke range. Since precise valve movement directly affects system stability, the device uses optimized signal processing to minimize overshoot and achieve consistent alignment with the control signal.

Key performance specifications include:

Input Signal: 4–20 mA analog control, supporting industry-standard loop systems.

Air Supply Range: Built to handle typical instrument air requirements, therefore maintaining constant actuator pressure.

Air Consumption: Low consumption design enhances efficiency and reduces system load.

Stroke Capacity: Works effectively with linear and rotary actuators across standard stroke sizes.

Feedback System: Integrated non-contact sensor technology ensures long operation without drift.

Operating Temperature: Wide temperature tolerance supports stable function in harsh environments.

Protection Rating: Industrial-grade sealing resists moisture, dust, and corrosive atmospheres.

Because the VALMET ND9106HNT maintains stable feedback accuracy during fast changes, operators gain the confidence needed for continuous process control.

3. Diagnostic and Monitoring Capabilities

Modern plants rely on predictive insights, and the VALMET ND9106HNT assists by delivering real-time diagnostic feedback. Through integrated monitoring tools, technicians track valve friction, travel curve irregularities, and actuator performance trends. Consequently, early detection of mechanical wear becomes easier, which reduces unexpected downtime.

Additionally, the internal electronics continuously verify signal quality. When the device detects irregular control input, it alerts the operator through clear diagnostic indicators. Therefore, maintenance teams can intervene quickly instead of waiting for major performance degradation.

4. Integration and System Compatibility

The VALMET ND9106HNT connects smoothly with common control systems, and installation requires no specialized protocol converters. Its 4–20 mA interface works naturally with DCS and PLC platforms, so engineers experience a simplified wiring process. Furthermore, the device supports standardized mounting accessories, which helps users avoid unnecessary adaptation tasks.

The positioner also integrates with advanced air supply systems, and its robust internal valves ensure efficient airflow distribution. In addition, the VALMET ND9106HNT maintains stable behavior even when pressure fluctuates, and this characteristic protects downstream equipment from unstable operation.

5. Reliability, Maintenance, and Industrial Benefits

Because the VALMET ND9106HNT uses contactless feedback components, it significantly reduces wear points. As a result, service intervals become longer and overall lifecycle cost decreases. The device logs operating data continuously, so technicians can review historical behavior to evaluate valve health over time.

Industries benefit from the VALMET ND9106HNT due to:

Strong control accuracy

Reduced drift

Lower air consumption

Durable construction

Faster calibration

Predictive diagnostics

Consequently, the positioner supports higher production consistency and lower maintenance cost across demanding sectors.

Reviews

There are no reviews yet.