Introduction

The ABB SPIIL02-L INFI-NET to INFI-NET Local Interface strengthens distributed control networks by enabling stable, fast, and synchronized communication between independent INFI-NET segments. Since modern plants depend on precise data coordination across controllers, gateways, and supervisory systems, the SPIIL02-L delivers a reliable bridge that enhances connectivity across multi-level industrial automation architectures. Moreover, the module organizes message flows efficiently, supports deterministic communication structures, and ensures continuous real-time operational visibility.

Because plant processes evolve quickly and frequently require rapid decision-making, users depend on high-quality communication hardware that manages large volumes of data without performance loss. Therefore, the SPIIL02-L incorporates optimized processing resources, robust electrical design, and intelligent routing logic that sustain network integrity even under demanding conditions. Additionally, its diagnostic features, extended environmental tolerance, and intuitive system behavior help technicians maintain consistent performance across long-term operations.

Core Functional Highlights

1. Local INFI-NET Segment Bridging

The SPIIL02-L links two INFI-NET segments within the same facility, allowing real-time data exchange between distributed controllers. As a result, operational variables, control instructions, event tags, and alarm information move easily across the entire network.

2. High-Speed Frame Processing

Since communication speed influences plant efficiency, the module processes large data frames with minimal delay. Furthermore, it prioritizes essential messages and organizes communication cycles so the network maintains smooth operation even when traffic levels increase.

3. Strong Protocol Compatibility

The module works seamlessly within ABB’s INFI-NET protocol. Consequently, users benefit from deterministic communication timing, structured message sequencing, time-tag consistency, and error-checked data framing.

4. Advanced Diagnostics for Efficient Maintenance

Front-panel indicators display communication status, processor activity, error conditions, and network integrity. Because of this visibility, technicians identify issues quickly and maintain stable system performance.

5. Straightforward System Integration

Although industrial networks often include many layers, the SPIIL02-L integrates naturally into existing ABB INFI-NET frameworks. Moreover, host systems, controllers, HMIs, and gateways interact with the module without requiring complex configuration adjustments.

Technical Specifications and Parameters

Electrical Characteristics

Power Supply: 5 VDC regulated

Typical Power Consumption: 6–8 W

Backplane Interface: INFI-NET compatible

Electrical Noise Protection: Integrated shielding and filtering components

The module maintains stable operation even when voltage conditions fluctuate or electrical noise levels rise.

Communication Specifications

INFI-NET Compatibility

Designed exclusively for INFI-NET to INFI-NET communication

Supports full-duplex real-time data exchange

Maintains synchronized communication frames between network segments

Data Handling Capabilities

High-speed message transit between distributed controllers

Intelligent frame buffering that supports peak demand periods

CRC-based error-checking for clean data delivery

Sequence-managed communication flows that avoid collision conditions

Timing and Synchronization

Supports INFI-NET network timing requirements

Consistent propagation of controller timestamps

Maintains event-order accuracy across interconnected segments

Protocol Performance

Structured data routing for operational variables, alarms, and events

Efficient control-message support for supervisory systems

Organized priority scheduling that improves network stability

Environmental Performance

Operating Environment

Operating Temperature: 0°C to +60°C

Storage Temperature: –40°C to +85°C

Humidity: 5–95% non-condensing

EMI Resistance: Designed for industrial electromagnetic conditions

Vibration/Noise Rating: Suitable for cabinet-mounted industrial hardware

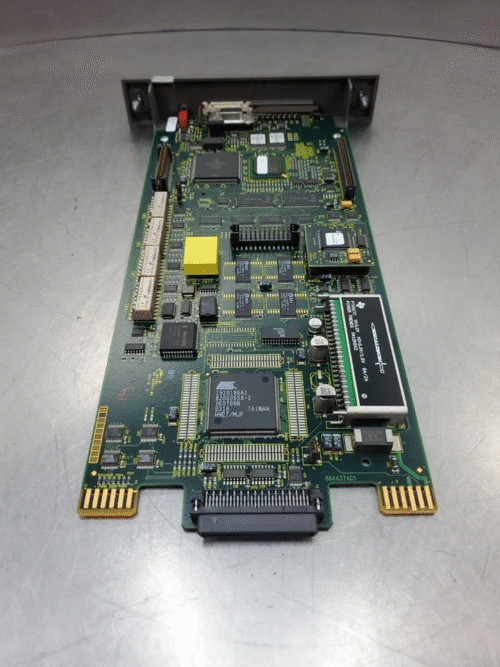

Physical Form Factor

Standard ABB/Bailey INFI-NET module housing

Card-style design for rack-based installation

Convection-cooled structure with internal airflow paths

Durable circuit board with reinforced components

Internal Hardware Architecture

Processing Capabilities

High-reliability embedded communication processor

Efficient scheduling algorithms that prioritize essential messages

Stable execution environment for continuous communication tasks

Memory Resources

Program Memory: Flash/EPROM-based firmware

Data Memory: High-speed RAM supporting temporary frame storage

Diagnostic Memory: Local storage for logs and error conditions

Hardware Monitoring

Voltage monitoring circuits

Thermal protection logic

Watchdog processor supervision that maintains stable activity

Software and Configuration Functions

Configuration Support

Works with ABB engineering and diagnostic tools

Supports network address assignment and routing logic adjustments

Interacts with supervisory systems, historians, and SCADA platforms

Data Structuring

Consistent variable mapping between connected INFI-NET networks

Structured address hierarchy that simplifies system engineering

Compatibility with large-scale plant modeling applications

Diagnostic Tools

Real-time system status visibility

Clear communication log outputs

Error recording that supports predictive maintenance

Application Scenarios

1. Multi-Segment Distributed Control Systems

Large industrial facilities rely on the SPIIL02-L to unify network segments while sustaining efficient real-time communication.

2. Power Generation Plants

Turbine control, boiler management, safety systems, and plant coordination benefit from the module’s stable processing and synchronized data exchange.

3. Chemical and Petrochemical Manufacturing

Processes involving continuous flow control and precision instrumentation depend on fast, accurate variable transmission between networked controllers.

4. SCADA System Gateways

SCADA servers receive consistent real-time data because the module ensures stable cross-segment communication.

5. High-Availability Redundant Architectures

The SPIIL02-L supports redundant network layouts where seamless communication between primary and secondary segments becomes essential.

Advantages of the SPIIL02-L

1. Strong Communication Stability

The module organizes message flow efficiently, creating a dependable and consistent network environment even during peak activity.

2. Scalable Integration

Users expand their INFI-NET environment easily by adding more segments or modules without major system changes.

3. High Reliability in Harsh Conditions

The durable design supports long-term use in environments with temperature variations, vibration, or electrical interference.

4. Improved Network Visibility

Clear diagnostics, organized logs, and intuitive indicators help technicians maintain full operational awareness.

5. Optimized Large-Data Handling

The SPIIL02-L manages thousands of variables with stable throughput, which enhances real-time control decisions.

Conclusion

The ABB SPIIL02-L INFI-NET to INFI-NET Local Interface strengthens plant-wide automation by offering reliable communication, rapid processing, environmental durability, and scalable integration. Its intelligent routing logic, high-speed data handling, and consistent diagnostic tools support modern industrial applications that require accuracy, reliability, and real-time coordination. Moreover, its robust architecture ensures long-term dependability, making it an essential component of advanced ABB INFI-NET distributed control systems.

Reviews

There are no reviews yet.