ABB FREQUENCY COUNTER MODULE 1 INPUT SPFCS01 – Technical Specifications and Performance Overview

Introduction

The SPFCS01 Frequency Counter Module stands out as one of the most reliable single-input frequency measurement units designed for ABB industrial control systems. It supports high-precision measurement tasks within distributed control systems, and it integrates seamlessly with automation platforms that require real-time detection of pulse signals, encoder outputs, turbine feedback, and rotational monitoring data. Because modern plants demand stable and actionable frequency information, the SPFCS01 offers a strong balance of resolution, measurement speed, electrical robustness, and environmental durability.

This article explores the technical specifications, the operating principles, the functional structure, and the application scope of the SPFCS01 while maintaining an SEO-optimized, reader-friendly format.

Module Architecture and Measurement Principles

The SPFCS01 relies on a high-resolution timing architecture. It reads an incoming pulse train and converts the timing differences into accurate frequency values. Moreover, it uses a continuous sampling process, and therefore, it delivers stable readings even when the plant has electrical noise or inconsistent pulse signals.

The module processes every input cycle through a micro-timing counter. Thus, each measured edge receives an accurate timestamp. Consequently, the internal calculation engine converts the timestamp sequence into a final frequency output.

Furthermore, this module maintains full compatibility with the ABB I/O subsystem design. Hence, its electrical interface allows controllers to obtain frequency values as scaled engineering units without requiring external signal conditioning.

Electrical Specifications

A frequency counter module must handle variations in voltage, signal shapes, and industrial noise. The SPFCS01 supports this through a rugged set of electrical characteristics:

Input Signal Characteristics

Number of Inputs: 1

Input Signal Type: Pulse, square wave, sensor signal, magnetic pickup

Input Voltage Range: 5–24 VDC typical

Input Impedance: High-impedance threshold for noise reduction

Minimum Pulse Width: 20–50 μs depending on signal quality

Maximum Pulse Frequency: 20 kHz typical

Input Isolation: 1500 V galvanic isolation

Internal Timing Engine

Resolution: Microsecond-class timing

Accuracy: 0.01% or better under stable conditions

Update Rate: High-speed computation for real-time frequency tracking

Counter Type: Edge-triggered rising or falling selectable

Because the input stage rejects common-mode interference, the module performs steadily even when installed inside cabinets with heavy AC loads or high-current drives.

Output and System Integration

The SPFCS01 offers fully digitalized frequency values so controllers can use frequency information directly in logic, automation calculations, and speed control loops.

System Interface

Communication Method: Native ABB I/O backplane

Data Format: Engineering units or raw frequency values

Update Cycle: Synchronized with controller scan time

Error Reporting: Over-range, signal loss, diagnostics flag

Thus, the controller receives actionable data without needing a separate PLC counter card or external converter.

Environmental Performance

Because frequency modules often work inside hot, vibration-heavy industrial cabinets, the SPFCS01 includes strong environmental resistance.

Operating Temperature: –20°C to +70°C

Storage Temperature: –40°C to +85°C

Humidity: 5–95% non-condensing

Shock and Vibration: Meets industrial IEC standards

EMI Immunity: Designed for noisy electrical enclosures

Therefore, the module maintains stable timing even in demanding environments.

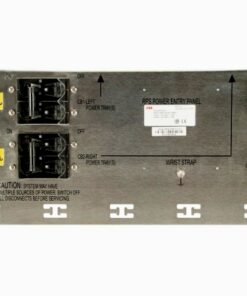

Mechanical Design

The module follows ABB’s modular I/O structure. Each unit installs directly into an I/O rack and locks in place securely.

Mounting Method: Backplane rack slot

Cooling Method: Passive convection

Dimensions: Standard ABB module size (varies slightly by system version)

Weight: Lightweight housing for simplified installation

The compact design allows dense I/O population inside control cabinets.

Functional Features

1. High-Accuracy Frequency Measurements

The timing engine processes every signal edge precisely. As a result, the module resolves small frequency changes and supports high-resolution speed monitoring.

2. Real-Time Diagnostics

Diagnostic flags include input loss, invalid frequency, over-range conditions, and timing faults. Therefore, operators can detect failures quickly.

3. Flexible Engineering Unit Scaling

Users can scale outputs to RPM, Hz, flow rate, or velocity. Consequently, one module can support many industrial measurement tasks.

4. Wide Compatibility

Because of the universal pulse input design, the SPFCS01 works with sensors such as:

Magnetic pickups

Optical encoders

Turbine sensors

Flow transmitters

Motor speed pickups

This flexibility increases system usage across multiple industries.

Application Scenarios

Power Generation

Turbine speed feedback and generator frequency monitoring require accurate and rapid measurement. The SPFCS01 handles high-speed signals successfully.

Oil & Gas

Pipeline turbines and compressor systems rely on stable pulse-based feedback. Thus, the module improves process stability.

Chemical and Petrochemical

Agitator speed, pump monitoring, and flowmeter frequency detection depend on continuous and reliable readings.

Manufacturing Automation

The module supports conveyor speed tracking, robotic motion analysis, and motor RPM feedback.

Water & Wastewater

It works well with turbine-type flowmeters and pump monitoring systems.

Advantages for Industrial Operators

High Reliability

Continuous edge detection ensures real-time updates.

No External Conditioning Required

Direct connection to most pulse sensors simplifies system design.

Improved Diagnostics

Fault flags allow plants to react faster.

Low Maintenance

Rugged design reduces downtime and component replacement frequency.

Conclusion

The SPFCS01 FREQUENCY COUNTER MODULE provides robust, precise, and real-time frequency measurement capabilities for demanding industrial automation tasks. Because it integrates seamlessly with ABB systems and supports a wide range of sensor types, it remains a core component for speed, motion, and flow monitoring applications. The combination of electrical isolation, rapid update cycles, and high-resolution timing makes it an excellent solution for modern plants seeking accurate frequency measurement within a compact module footprint.

Reviews

There are no reviews yet.