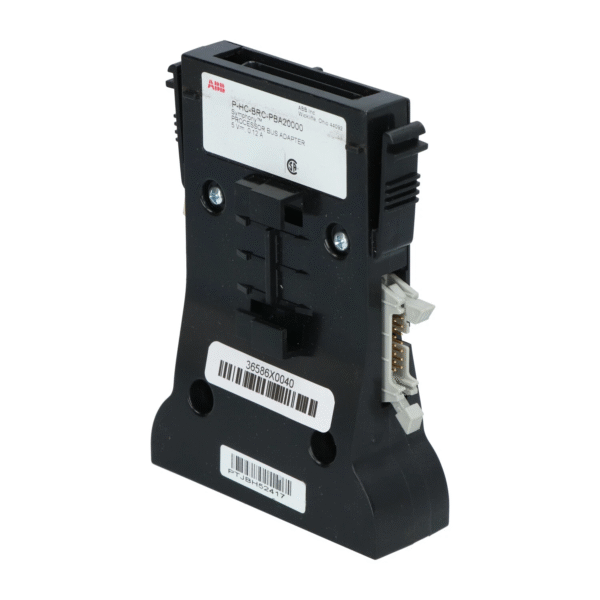

ABB Processor Bus Adapter PHCBRCPBA20000 – Technical Description and Specifications

The ABB Processor Bus Adapter PHCBRCPBA20000 strengthens high-level controller communication within advanced industrial automation systems. Because industrial environments evolve quickly, plants need a communication interface that transfers data efficiently, integrates modules smoothly, and supports long-term reliability. Therefore, this adapter enters the architecture as a core communication element that links controllers with distributed components while maintaining continuous operational stability. Moreover, its design aligns with ABB’s long-standing focus on performance, modularity, and industrial-grade durability, which makes it a dependable choice for mission-critical applications.

1. Structural Design and Hardware Characteristics

The PHCBRCPBA20000 uses a compact, rigid construction that fits seamlessly inside ABB system cabinets. Its printed circuit structure optimizes signal routing, and it minimizes electromagnetic interference through refined track geometry. Furthermore, the module uses industry-standard connectors that ensure mechanical integrity, therefore promoting dependable data transmission even when the system runs under thermal or electromagnetic stress. The adapter includes multi-layer protection circuitry that strengthens resilience and avoids communication interruptions during high-load operation.

Additionally, the front panel arranges indicator LEDs clearly, so engineers track bus status, link quality, and real-time transmission activity without interpretation delays. The mechanical housing uses flame-retardant materials that support safe installation in energy-intensive environments. As a result, the device functions reliably across wide operating temperature ranges and still maintains optimal electrical behavior.

2. Communication Features and Bus Interface Performance

The PHCBRCPBA20000 supports high-speed processor-level communication and bridges controllers to core ABB communication buses. Because sophisticated automation cells require fast link cycles, the adapter manages data polling, synchronization signals, and module addressing efficiently. It maintains deterministic timing, and it ensures that controllers exchange data consistently with local or remote nodes.

Moreover, the module optimizes throughput by using intelligent buffering, so the system handles continuous streams of I/O updates without congestion. Its command-handling engine resolves data requests rapidly, and it supports multi-node topologies so engineers expand networks without redesigning the backbone.

Key Communication Capabilities

Processor-level high-speed bus interface

Stable frame synchronization

Low-latency request/response cycles

Error monitoring and real-time diagnostics

High-integrity signal conditioning

These capabilities allow the PHCBRCPBA20000 to integrate into large DCS or PLC networks while sustaining uninterrupted performance.

3. Electrical Specifications

The adapter maintains consistent electrical behavior across a wide range of industrial conditions. Its power regulation circuitry ensures smooth internal voltage levels, therefore protecting sensitive processor interfaces. The following specifications outline its electrical performance:

Nominal Operating Voltage: 24 VDC (system-supplied)

Typical Power Consumption: < 4 W

Logic Interface Voltage: 5 VDC internal regulation

Signal Isolation: ≥ 1500 V galvanic channel isolation

Noise Immunity: Compliant with industrial EMC standards

Operating Temperature Range: –20°C to +70°C

Storage Temperature Range: –40°C to +85°C

Because industrial processors rely heavily on stable communication modules, these parameters ensure that the adapter runs efficiently across complex control architectures.

4. Software Integration and Configuration Behavior

The PHCBRCPBA20000 integrates smoothly with ABB configuration tools, so deployment simplifies significantly. During setup, engineers configure bus addresses, link speeds, and diagnostic levels through user-friendly software environments. Moreover, the module synchronizes automatically with ABB controllers after initialization, which reduces commissioning time.

It supports real-time self-diagnostics and continuously reports communication quality. Therefore, maintenance teams identify abnormalities quickly and reduce troubleshooting cycles. The adapter logs link interruptions, retries, and controller communication states so long-term reliability improves as system conditions change.

5. Application Scenarios and Industrial Use Cases

Because of its communication stability and processor-level integration, the PHCBRCPBA20000 fits seamlessly into a wide array of industries:

Power generation and turbine control networks

Petrochemical and refinery automation

Pulp and paper process systems

Pharmaceutical production lines

Steel and metallurgy control systems

Water and wastewater treatment automation

In each environment, the adapter ensures that controllers synchronize with distributed modules efficiently, and it supports real-time command execution across multiple levels of a plant network.

6. Reliability and Maintainability Advantages

Continuous uptime defines modern industrial plants, so the PHCBRCPBA20000 improves reliability through several design strategies. It reduces signal distortion, avoids timing drift, and maintains link stability during voltage fluctuations. Furthermore, its modular format allows quick replacement during maintenance windows, so technicians swap modules without shutting down large sections of the system.

The diagnostics architecture enhances predictive maintenance because engineers track link quality over long periods. Additionally, firmware-level error counters help identify aging components so plants avoid unexpected communication failures.

7. Summary of Technical Specifications

| Parameter Type | Specification |

|---|---|

| Product Type | Processor Bus Adapter |

| Model | PHCBRCPBA20000 |

| Communication Speed | High-speed processor bus |

| Voltage Input | 24 VDC |

| Power Use | < 4 W |

| Isolation | ≥1500 V |

| Diagnostics | LED indicators + software logs |

| Operating Temp | –20°C to +70°C |

| Installation | Rack/cabinet mount |

Through these specifications, the module offers long-term stability, consistent performance, and seamless integration into ABB control architectures.

Reviews

There are no reviews yet.