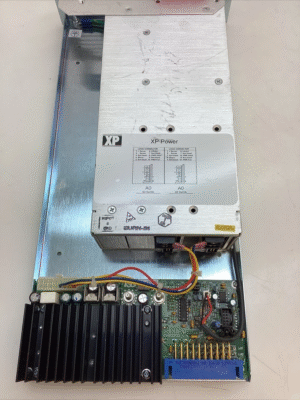

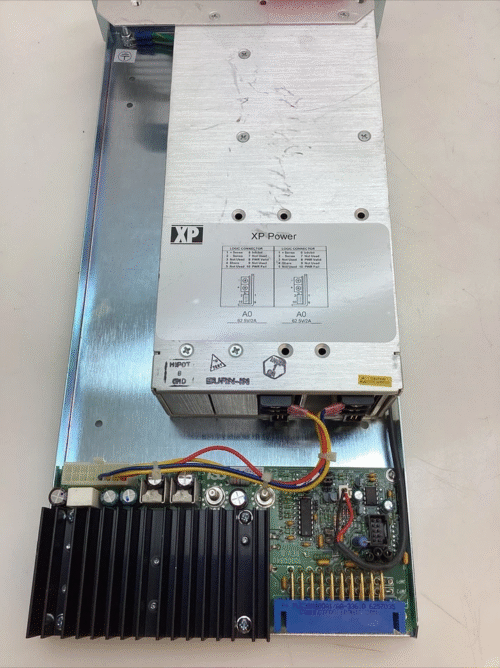

The ABB PHARPS00010000 Power Module stands as a vital component for modern industrial automation systems, providing stable power distribution, precise control, and comprehensive monitoring capabilities. Designed for integration into ABB control cabinets, this module ensures consistent energy delivery and protects sensitive electronic components from fluctuations and disturbances. Because industrial environments demand high reliability, the PHARPS00010000 combines advanced electrical design with durable construction, enabling long-term operational stability and minimizing system downtime.

This in-depth description examines the PHARPS00010000’s electrical specifications, mechanical architecture, monitoring capabilities, environmental resilience, installation benefits, and operational advantages. Engineers and plant operators can understand why this module strengthens ABB cabinet performance and ensures reliable operations across a variety of industrial processes.

1. Core Functionality and Applications

The PHARPS00010000 functions as a central power supply for ABB control cabinets, regulating voltage and current across connected PLCs, I/O modules, communication devices, and auxiliary components. By maintaining precise energy distribution, it prevents overloading, voltage drops, and power disturbances, which are critical for uninterrupted industrial operations.

Key applications include:

ABB DCS cabinets and modular control systems

PLC-based automation environments

Industrial process power distribution

Voltage and current monitoring in critical circuits

Integration into redundant cabinet systems for high availability

As industrial systems evolve, operators require power modules that adapt to increased load requirements and system expansions. The PHARPS00010000 delivers this scalability, ensuring reliable operation across diverse industrial configurations.

2. Electrical Specifications and Performance

2.1 Voltage Regulation

The PHARPS00010000 supplies both AC and DC outputs with precise voltage control. Each output channel ensures stable energy delivery, even under peak load conditions. This stability supports the uninterrupted operation of sensitive electronic modules and peripherals.

2.2 Surge and Transient Protection

Equipped with advanced surge suppression circuits and electromagnetic interference (EMI) filtering, the module safeguards downstream components from spikes, transient surges, and electrical noise. This protection guarantees clean power distribution and minimizes potential disruptions in automation operations.

2.3 Current Handling and Load Balancing

The module features intelligent current management that distributes power efficiently across multiple outputs. Overcurrent protection automatically responds to abnormal conditions, ensuring safety, preventing damage, and maintaining continuous operation.

3. Mechanical Design and Industrial Durability

3.1 Reinforced Housing

The PHARPS00010000 features an industrial-grade metal enclosure designed to withstand vibration, mechanical shock, and high-temperature environments. Its robust construction ensures long-term reliability, even in demanding industrial settings.

3.2 Compact Form Factor

The module’s design allows installation in standard ABB cabinet slots without modifications. Its compact layout supports multiple modules within the same cabinet while maintaining efficient airflow and accessibility.

3.3 High-Quality Connectors and Interfaces

Precision-engineered connectors ensure secure and low-resistance electrical contact. These connectors minimize energy loss, maintain signal integrity, and simplify installation and maintenance procedures.

4. Monitoring and Diagnostic Capabilities

The PHARPS00010000 provides real-time monitoring of voltage, current, temperature, and load across all output channels. Front-panel LEDs indicate operational status, allowing engineers to quickly identify issues. Furthermore, the module integrates with supervisory control systems for remote monitoring, data logging, and trend analysis.

This continuous monitoring enables predictive maintenance, early detection of abnormal conditions, and proactive interventions to maintain system reliability and prevent unexpected downtime.

5. Thermal Management and Environmental Resilience

5.1 Efficient Heat Dissipation

The module’s internal layout promotes efficient thermal management. Thermal channels and metallic casing allow convection to dissipate heat, maintaining stable temperatures even during continuous high-load operation.

5.2 Industrial Environmental Tolerance

The PHARPS00010000 operates reliably under a wide temperature range, high humidity, dust, and vibration. This environmental resilience ensures uninterrupted performance in harsh industrial conditions, including chemical plants, power generation facilities, and heavy manufacturing environments.

6. Integration and Compatibility

The PHARPS00010000 integrates seamlessly with ABB control cabinets, DCS systems, and standard modular racks. It supports:

I/O modules and field devices

Communication interfaces

Redundant cabinet power configurations

Supervisory and HMI integration

Compatibility with both legacy and modern ABB cabinet systems allows easy upgrades and expansions without interrupting ongoing operations. Modular integration simplifies installation and supports system scalability.

7. Redundancy and High-Availability

The PHARPS00010000 supports dual-module redundancy, enabling continuous operation even during module maintenance or failure. Parallel configurations allow load sharing and seamless failover, minimizing operational downtime and ensuring reliable process control.

8. Maintenance Efficiency and Lifecycle Management

Engineers benefit from minimal maintenance requirements due to the module’s high-quality components and protective design. Accessible connectors, clear labeling, and diagnostic LEDs simplify troubleshooting. Predictive maintenance strategies, supported by real-time monitoring, reduce lifecycle costs and enhance overall operational efficiency.

9. Key Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ABB PHARPS00010000 |

| Function | Power supply, monitoring, and control for cabinets |

| Input Voltage | AC/DC regulated input |

| Output Channels | Multiple outputs for distributed devices |

| Monitoring | Voltage, current, temperature, load |

| Protection | Surge, transient, overcurrent |

| Housing | Industrial-grade reinforced metal |

| Cooling | Convection and thermal channel design |

| Installation | Standard ABB cabinet mount |

| Environmental | Temperature, humidity, vibration resistant |

| Redundancy | Dual-module support for high availability |

| Communication | Supervisory system integration |

10. Operational Benefits

The ABB PHARPS00010000 enhances cabinet and system performance by:

Providing stable and precise power for connected devices

Supporting advanced monitoring for proactive maintenance

Enabling modular integration with I/O and communication units

Withstanding extreme industrial environmental conditions

Reducing downtime through redundancy and high-availability support

Optimizing energy efficiency and load balancing

Simplifying installation and maintenance workflows

These advantages make the PHARPS00010000 a reliable, safe, and efficient solution for modern industrial automation systems.

Conclusion

The ABB PHARPS00010000 Power Module provides robust power distribution, accurate monitoring, and seamless control for industrial cabinets. Its durable electrical and mechanical design, coupled with advanced diagnostic capabilities, ensures operational reliability and efficiency. By supporting redundancy, modular integration, and environmental resilience, the PHARPS00010000 enhances ABB cabinet performance, minimizes downtime, and strengthens overall industrial automation infrastructure.

Reviews

There are no reviews yet.