The ABB IEMMU22 Cabinet Module serves as a critical element in modern industrial automation systems, delivering robust power distribution, advanced monitoring, and precise control across multiple cabinet-connected devices. Designed for ABB control cabinets, the IEMMU22 ensures consistent energy flow, enhances operational reliability, and provides extensive diagnostic feedback for plant operators and engineers. Because industrial operations demand uninterrupted functionality, the module integrates high-performance electrical design with durable mechanical construction to maintain seamless operation even under challenging conditions. Additionally, it supports integration with various I/O, communication, and supervisory devices, ensuring a fully coordinated automation infrastructure.

This comprehensive overview explores the IEMMU22’s architecture, electrical parameters, mechanical design, monitoring and diagnostic features, environmental resilience, installation benefits, and operational advantages. By understanding these aspects, engineers and system integrators can appreciate why the IEMMU22 enhances ABB cabinet performance and strengthens industrial reliability across diverse applications.

1. Core Functionality and Application Scope

The IEMMU22 functions as a central hub for distributing power within ABB automation cabinets. It regulates voltage and current across connected PLCs, I/O modules, communication units, and auxiliary devices. Because precise energy management underpins stable industrial control, the IEMMU22 ensures consistent operation, prevents overloading, and maintains uninterrupted system performance.

Common applications include:

ABB DCS and modular control cabinets

PLC-based automation systems

Power management for critical industrial processes

Monitoring voltage, current, and temperature in cabinet environments

Integration into redundant cabinet architectures for high availability

Industrial plants increasingly require scalable modules capable of supporting future expansions and additional load demands. The IEMMU22 addresses this need by providing sufficient capacity while maintaining consistent operation across all outputs.

2. Electrical Characteristics and Performance

2.1 Voltage Regulation and Load Management

The IEMMU22 distributes both DC and AC voltages with high precision. Each output channel maintains stable voltage delivery, even under fluctuating load conditions, ensuring reliable performance for sensitive modules and peripheral devices.

2.2 Surge Protection and Electromagnetic Compatibility

The module incorporates surge suppression and EMI filtering to protect connected devices from electrical spikes and transient disturbances. This capability prevents interruptions in control operations, safeguards downstream equipment, and ensures clean power for all cabinet components.

2.3 Current Handling and Overload Protection

The IEMMU22 monitors current flow in real time and applies overcurrent protection when necessary. By evenly distributing load and quickly responding to abnormal current levels, the module maintains safety, prevents damage, and sustains continuous operation.

3. Mechanical Design and Industrial Durability

3.1 Robust Housing Construction

The IEMMU22 employs a reinforced industrial-grade metal casing that withstands vibration, mechanical impact, and high-temperature conditions. This robust design ensures stable operation in demanding industrial environments, where cabinets house multiple high-power modules.

3.2 Compact and Space-Efficient Layout

The module fits standard ABB cabinet slots without modification. Its compact form factor enables engineers to install multiple modules within a single cabinet while maintaining airflow, accessibility, and heat dissipation efficiency.

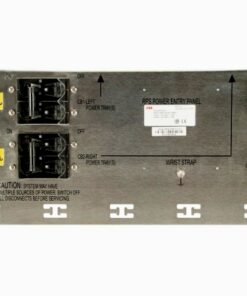

3.3 High-Quality Connectors and Interfaces

Precision-engineered connectors ensure low-resistance contact and secure electrical continuity. Labeling clarity simplifies installation and maintenance, while connector design reduces energy loss and maintains signal integrity throughout the cabinet.

4. Monitoring and Diagnostic Features

The IEMMU22 integrates comprehensive monitoring functionality, including real-time voltage, current, temperature, and load measurements. Front-panel LED indicators provide instant operational feedback, while remote supervisory systems access detailed data for predictive maintenance and operational analysis.

Furthermore, the module logs event histories, enabling engineers to identify trends, detect anomalies early, and implement corrective actions before minor issues escalate. This continuous monitoring enhances reliability and reduces the likelihood of unexpected downtime.

5. Thermal Management and Environmental Resilience

5.1 Efficient Heat Dissipation

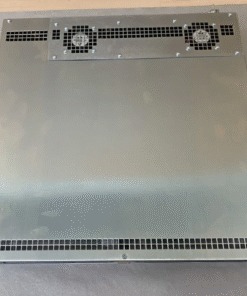

The IEMMU22 employs an optimized internal layout that promotes convection and thermal transfer. Thermal channels and metallic casing facilitate passive cooling, preventing overheating and ensuring reliable long-term operation.

5.2 Industrial Environmental Tolerance

The module withstands wide temperature ranges, high humidity, airborne dust, and industrial vibrations. Its resilient design ensures stable operation in harsh conditions, such as chemical plants, power generation facilities, steel mills, and heavy manufacturing environments. By maintaining operational integrity under environmental stress, the IEMMU22 ensures uninterrupted control.

6. Integration and System Compatibility

The IEMMU22 seamlessly integrates with ABB control cabinets, DCS, PLC systems, and standard rack architectures. It interfaces with:

I/O modules and field devices

Communication and network modules

Redundant power configurations

Supervisory and HMI systems

Compatibility with legacy and modern ABB cabinet architectures enables engineers to implement upgrades without interrupting ongoing operations. Modular connectivity simplifies installation and configuration, allowing flexible adaptation to evolving plant requirements.

7. Redundancy and High-Availability Support

The IEMMU22 supports dual-module redundancy, enabling continuous operation even if one module requires maintenance or experiences failure. Parallel configurations distribute load and provide seamless failover, minimizing operational downtime. This redundancy enhances system reliability and ensures mission-critical processes continue without interruption.

8. Maintenance and Lifecycle Efficiency

The IEMMU22 requires minimal maintenance due to high-quality industrial components and protective design features. Accessible connectors and diagnostic LEDs simplify troubleshooting, allowing technicians to quickly identify and resolve issues. Predictive monitoring facilitates planned maintenance, reduces total lifecycle costs, and improves overall operational efficiency.

9. Key Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ABB IEMMU22 |

| Function | Cabinet power distribution, monitoring, and control |

| Input Voltage | AC/DC regulated input |

| Output Channels | Multiple, distributed for connected devices |

| Monitoring | Voltage, current, temperature, load |

| Protection | Surge, transient, overcurrent |

| Housing | Industrial-grade reinforced metal |

| Cooling | Convection and thermal channel design |

| Installation | Standard ABB cabinet mount |

| Environmental | Temperature, humidity, vibration resistant |

| Redundancy | Dual-module support for high availability |

| Communication | Supervisory system integration supported |

10. Operational Advantages and Benefits

The IEMMU22 improves industrial cabinet performance by:

Delivering stable and regulated power to all connected modules

Supporting advanced monitoring for proactive maintenance and fault detection

Enabling modular integration with communication and I/O devices

Withstanding extreme environmental conditions including vibration, heat, and humidity

Reducing downtime through redundancy and high-availability configurations

Enhancing energy efficiency and load balancing across connected circuits

Simplifying installation, configuration, and maintenance for engineering teams

By providing these benefits, the IEMMU22 ensures safe, reliable, and efficient operation across industrial automation systems, empowering plants to achieve higher productivity and lower operational risk.

Conclusion

The ABB IEMMU22 Cabinet Module delivers robust power distribution, precise monitoring, and seamless control for industrial automation cabinets. Its advanced electrical architecture, durable mechanical design, and comprehensive diagnostic capabilities make it indispensable in demanding industrial environments. The module ensures stable operation, protects downstream components, and provides continuous real-time data for supervisory systems. By supporting redundancy, high-availability configurations, and modular integration, the IEMMU22 strengthens ABB cabinet performance, reduces downtime, and enhances overall system efficiency, making it a critical component in modern industrial automation infrastructure.

Reviews

There are no reviews yet.