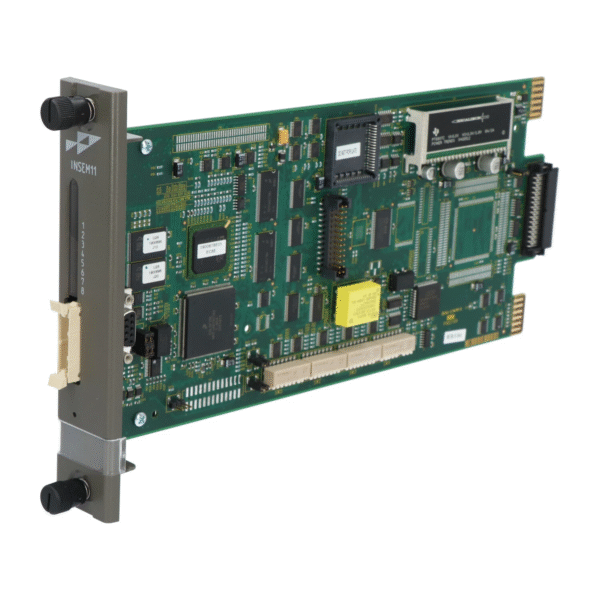

The ABB INSEM11 Sequence of Events Master Module offers a powerful and accurate way to capture, organize, and analyze time-critical occurrences inside industrial automation systems. Since modern plants operate with increasingly high demands on reliability, accuracy, and transparency, engineers rely on advanced SOE (Sequence of Events) modules to support every layer of system decision-making. Therefore, the INSEM11 enters these environments with a high-efficiency architecture, strong data precision, and smart synchronization features that support both real-time operation and long-term system optimization.

To start, the INSEM11 delivers microsecond-level time resolution. Consequently, users track even the fastest transitions within complex production processes. Moreover, this precise timing enables operators to understand root causes faster and, thus, take corrective actions with outstanding confidence. Because accurate timestamps support maintenance strategies, troubleshooting, and compliance reporting, the INSEM11 significantly elevates engineering productivity and operational stability.

Furthermore, ABB designs the INSEM11 with a modular approach, so it integrates smoothly into ABB Bailey and compatible control architectures. Additionally, engineers install it easily within existing frames, and they configure it without interrupting other modules. As a result, automation systems grow more scalable, allowing operators to expand capabilities whenever new requirements appear.

1. Key Functional Features

The INSEM11 includes a collection of high-value features that strengthen event management inside industrial environments. These functions work together to ensure that every transition—from alarms to switch status changes—enters the system instantaneously and with full clarity.

1.1 High-Resolution Event Time-Stamping

The module provides extremely fine time resolution, often reaching microsecond-grade precision. Therefore, operators track event order with total accuracy, even when dozens of signals change within fractions of a second. Since event order often determines the difference between a useful diagnosis and an uncertain conclusion, this capability becomes one of the most valuable strengths of the INSEM11.

1.2 Centralized Event Coordination

Because the INSEM11 functions as a “master” module, it gathers information from connected SOE input modules and organizes them into a unified event sequence. Consequently, engineers receive clear, chronological reports instead of scattered signal logs. This central coordination increases clarity and speeds up the decision-making cycle across maintenance teams and operations personnel.

1.3 Real-Time Clock Synchronization

The module maintains highly stable timing performance through synchronized communication with plant-wide time references. Moreover, it supports external synchronization signals, so users maintain accurate record timelines even in large distributed installations.

1.4 Robust Diagnostic Feedback

Operators receive continuous diagnostic information, allowing them to observe health conditions, communication status, and configuration integrity in real time. Furthermore, the module alerts users when specific operating limits approach, ensuring timely intervention and reducing risk.

2. Technical Specifications and Performance Parameters

Below is a detailed summary of typical specifications and operating parameters associated with the ABB INSEM11 SOE Master Module. These values help integrators understand compatibility, performance capability, and installation requirements within ABB control systems.

2.1 Electrical Specifications

Power Supply: Draws regulated power from the system backplane

Voltage Tolerance: Supports standard Bailey control system voltage ranges

Power Consumption: Low-power architecture ensures stable and efficient long-term operation

Surge Protection: Integrated protection circuits safeguard against electrical noise and transients

2.2 Timing and Event Handling

Timestamp Resolution: Microseconds or high-precision milliseconds depending on plant configuration

Maximum Event Throughput: Supports rapid event bursts without data loss

Clock Synchronization: Works with plant-wide clock systems, including external sync pulses

Event Buffer Capacity: Stores large quantities of events locally for secure retrieval

2.3 Communication and Protocols

Backplane Interface: Operates across the ABB Bailey INFI-90 or compatible architecture

Data Exchange Speed: High-frequency bus communication ensures instant data flow

Compatibility: Functions smoothly with associated input modules such as INIIT02, INICT03, etc.

Diagnostic Protocol: Provides internal status reports that integrate into the plant’s monitoring suite

2.4 Environmental Conditions

Operating Temperature Range: Suitable for demanding industrial cabinet environments

Humidity Resistance: Works reliably under moderate humidity conditions

EMC Compliance: Withstands electrical noise present in industrial plants

Mechanical Durability: Rugged PCB design ensures stable performance across long service lifetimes

2.5 Physical and Installation Data

Form Factor: Designed for standard ABB Bailey card frames

Connector Type: Uses system backplane connectors for communication and power

Cooling Requirements: Passive cooling through convection airflow inside the panel

Mounting Style: Slides into control rack without special tools

3. Application Scenarios Across Industries

Since the INSEM11 serves as a core event-tracking element in advanced control systems, it appears across a wide range of industries. Its speed, accuracy, and clarity make it especially valuable in systems where rapid state changes influence safety, reliability, or system performance.

3.1 Power Generation

Power plants require extremely accurate event sequences to analyze protective relay actions, turbine control logic transitions, and alarm cascades. Therefore, operators depend on the INSEM11 to clarify system behavior before, during, and after critical events.

3.2 Oil & Gas Processing

In refineries and gas handling facilities, rapid pressure, flow, or temperature changes often trigger alarms. Since slight timing differences may determine root causes, engineers use the INSEM11 to build reliable data for engineering review and failure prevention.

3.3 Chemical and Petrochemical Plants

Process upsets occur within milliseconds. Consequently, the INSEM11 helps maintenance teams pinpoint exact event paths that lead to plant trips, enabling safer restart and more informed troubleshooting.

3.4 Metals and Heavy Manufacturing

High-speed equipment demands precise sequence analysis. Moreover, the INSEM11 ensures operators track equipment status changes in real time, improving system efficiency and preventive maintenance strategies.

3.5 Water Treatment and Environmental Systems

Event history supports compliance with environmental operational regulations. Therefore, the INSEM11 provides clean, chronological reporting for audits and system performance evaluations.

4. Advantages of ABB INSEM11

The following advantages make the INSEM11 a strong choice for modern industrial applications:

Extremely accurate timestamping for reliable event reconstruction

Smooth integration with ABB Bailey control architectures

Fast communication speeds for dense event activity

Comprehensive diagnostics that support maintenance efficiency

Scalable design suitable for large and small systems

Stable long-term performance in demanding environments

Because these strengths work together, engineers improve fault analysis, reduce downtime, and create stronger predictive maintenance workflows.

5. Why Choose INSEM11 for Your Automation System

Engineers select the INSEM11 when they need high-resolution event data, system transparency, and extremely reliable sequencing logic. Moreover, it enhances operational intelligence and supports smarter decision-making across every department—from maintenance to engineering to operations.

Additionally, its ABB-engineered stability ensures dependable performance for many years, even in harsh industrial conditions. With its combination of diagnostics, clarity, and advanced timing, the INSEM11 significantly elevates any ABB Bailey-based automation platform.

Reviews

There are no reviews yet.