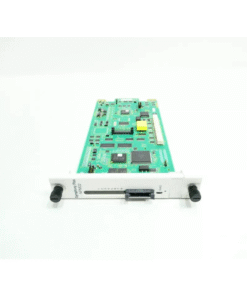

ABB IO MODULE SPHSS13 – Specifications and Features

The ABB SPHSS13 IO Module delivers reliable, high-performance input/output management for advanced industrial automation systems. Designed to integrate seamlessly with ABB PLCs and control networks, the SPHSS13 module ensures accurate signal processing, robust control, and efficient monitoring. By incorporating the ABB SPHSS13, engineers enhance operational efficiency, maintain system reliability, and optimize industrial processes across manufacturing, utilities, and process control environments.

Key Features

The ABB SPHSS13 IO Module offers multiple features that make it ideal for industrial applications:

Versatile I/O Configuration: Supports a range of analog and digital signals to meet varied process requirements.

High-Performance Processing: Rapid response ensures timely signal acquisition and control.

Reliable Operation: Durable design provides stability in harsh industrial environments.

Seamless Integration: Fully compatible with ABB PLCs, SCADA systems, and industrial networks.

Advanced Diagnostics: Monitors module performance and supports predictive maintenance strategies.

Maintenance Friendly: Simplifies panel organization and allows easy module replacement.

The SPHSS13 module delivers consistent and precise I/O management, ensuring operational excellence and safety in industrial systems.

Technical Specifications

The ABB SPHSS13 IO Module is engineered to meet rigorous industrial standards:

Module Type: Input/Output Module (SPHSS13)

Input Channels: Configurable analog and digital inputs

Output Channels: Configurable outputs for actuators, indicators, or control devices

Input Voltage Range: 24–230 VDC/AC

Accuracy: High precision for analog signal measurement

Response Time: Millisecond-level response for digital and analog signals

Operating Temperature: –20°C to +70°C

Humidity Range: 5–95% non-condensing

Mounting: DIN rail or panel mount for easy installation

Compliance: CE, UL, IEC certified for global industrial use

Weight: Lightweight design for convenient handling

Material: Durable industrial-grade components for long-term reliability

Applications

Manufacturing Automation

The SPHSS13 IO Module provides accurate signal monitoring and control in manufacturing plants. High-speed response allows efficient production line management and quality assurance.

Process Control

ABB SPHSS13 ensures precise control of pumps, valves, and sensors in chemical, pharmaceutical, and food processing industries, improving consistency, safety, and efficiency.

Power Systems and Utilities

The module monitors key electrical parameters in power plants and substations, enabling real-time event logging, fault detection, and preventive maintenance for critical systems.

Smart Industrial Systems

SPHSS13 supports smart factory implementations by integrating sensors, actuators, and PLCs, facilitating predictive maintenance, process optimization, and data-driven operations.

Maintenance and Best Practices

Maintaining the ABB SPHSS13 module ensures optimal performance:

Regular Inspections: Check connectors, wiring, and mounting stability.

Environmental Control: Operate within recommended temperature and humidity ranges.

Firmware Updates: Keep module firmware updated for compatibility and performance.

Diagnostics Monitoring: Review system logs to identify potential issues early.

Authorized Support: Contact Wuhan Yuli Automation Technology Co., Ltd and visit www.wuhanyuli.com for installation guidance and technical assistance.

Advantages of ABB SPHSS13

Reliable Signal Management: Ensures consistent analog and digital input/output processing.

High-Speed Response: Provides timely acquisition and control for critical processes.

Versatile Deployment: Compatible with multiple industrial environments and ABB PLCs.

Enhanced System Reliability: Durable design ensures long-term operational stability.

Operational Insights: Built-in diagnostics support maintenance and optimization strategies.

The ABB SPHSS13 IO Module delivers precise, reliable, and high-performance I/O management, ensuring operational efficiency, process accuracy, and flexibility for future industrial system expansions.

Reviews

There are no reviews yet.