Introduction to IMFCS01

The IMFCS01 Frequency Counter Module offers precise measurement for a wide range of industrial applications. Designed for control systems, it provides accurate real-time frequency data, ensuring efficient operation, stability, and safety in industrial processes. This guide highlights its specifications, technical parameters, installation recommendations, operational features, and best practices for maximizing module performance. By understanding its capabilities, engineers can optimize automation systems effectively and maintain high system reliability.

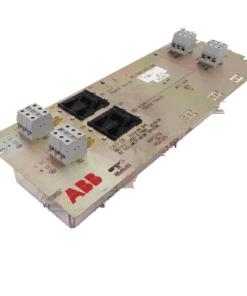

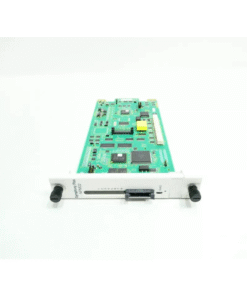

Product Overview

The IMFCS01 module features a single input channel capable of measuring a broad frequency range. It supports both low and high-frequency signals, ensuring flexibility in diverse industrial environments. The module integrates seamlessly with programmable logic controllers (PLCs), distributed control systems (DCS), and SCADA systems. Its robust construction withstands harsh industrial conditions, including temperature fluctuations, vibrations, and electrical noise, ensuring uninterrupted and accurate frequency monitoring.

Key Features

Single Input Channel: Handles one frequency source with exceptional accuracy.

Wide Frequency Range: Operates from very low Hz to high kHz or MHz frequencies.

High Precision: Provides low error rates and stable readings under dynamic conditions.

Robust Industrial Design: Resistant to electrical noise, temperature variations, and vibrations.

Compact Form Factor: Facilitates easy integration in standard industrial cabinets or racks.

These features make IMFCS01 ideal for applications that demand reliable frequency measurement and high system performance.

Electrical Specifications

The module operates at a standard industrial supply voltage, typically 24V DC, with minimal current consumption to maintain energy efficiency. Input impedance matches standard sensor outputs, allowing accurate signal processing without significant loss. Signal conditioning within the module ensures noise suppression and accurate frequency detection. Its high sampling rate ensures that fast signal changes are captured, delivering precise data to control systems without delay.

Input Signal Requirements

IMFCS01 accepts a variety of signal types, including TTL, square wave, and sine wave inputs. Users should verify that the input signal meets the specified voltage levels and waveform characteristics. Proper matching of signal type and configuration parameters enhances measurement accuracy and system stability.

Mechanical Specifications

The module has a rugged enclosure designed to resist environmental stress. Mounting options are compatible with standard automation racks, providing secure placement and vibration resistance. Its connectors support reliable electrical connections, minimizing the risk of intermittent signals. Compact dimensions allow space-saving integration into existing control cabinets, facilitating upgrades or new installations without major modifications.

Installation Guidelines

Pre-Installation Preparation

Before installing the IMFCS01 module, ensure that the system is powered off. Gather all necessary tools, verify module specifications, and inspect for physical damage. Clear the installation area from dust and contaminants to maintain safety and performance.

Mounting the Module

Secure the IMFCS01 module into the designated slot within the control rack. Align the module correctly to engage the backplane connection. Ensure that all mounting screws are tightened to prevent vibrations and maintain reliable connectivity.

Wiring Connections

Connect the frequency input signal using shielded cables to minimize electromagnetic interference. Check polarity and signal integrity to prevent measurement errors. Verify that all connections are secure before powering on the system.

Configuration and Setup

After installation, configure the module within the control system. Specify input signal type, scaling, measurement units, and sampling parameters. Use the controller interface or software tools to calibrate the module. Conduct initial test measurements to verify accuracy and reliability. Proper configuration ensures precise frequency readings for real-time monitoring and control.

Operational Features

IMFCS01 supports real-time monitoring of frequency signals, allowing operators to observe system behavior continuously. It provides stable readings even under fluctuating industrial conditions. Operators can set alarms for threshold values to detect deviations promptly. This capability minimizes operational risks and ensures continuous, efficient performance of industrial processes.

Troubleshooting

Common issues include signal noise, wiring errors, and misconfigured parameters. Begin by inspecting physical connections, ensuring correct cable types, and verifying input signal quality. Use system diagnostic tools to identify irregularities. Adjust module configuration or replace faulty components as needed. A systematic troubleshooting approach maintains system uptime and performance integrity.

Maintenance Best Practices

Regular inspection and maintenance enhance the reliability and lifespan of the IMFCS01 module. Check connectors, cables, and mounting periodically. Clean dust and debris to prevent overheating. Verify calibration annually or whenever the system undergoes significant changes. Updating firmware and control software ensures compatibility with evolving automation networks.

Industrial Applications

IMFCS01 modules are widely applied in multiple industries, including:

Manufacturing: Monitor rotational speed of motors, conveyors, and machinery.

Energy: Measure frequency in generators and turbines for power plants.

Process Control: Track pump, mixer, or conveyor speeds in chemical and water treatment facilities.

Automation Systems: Integrate frequency measurement into SCADA, PLC, and DCS environments.

Its versatility and precision make IMFCS01 a critical component in modern industrial operations.

Advantages for Operators

Operators benefit from:

Accurate, real-time frequency measurement

Seamless integration with existing automation systems

Reduced operational downtime due to reliable performance

Energy-efficient and robust industrial design

By implementing IMFCS01, operators can enhance process control, optimize productivity, and maintain system reliability.

Conclusion

The IMFCS01 Frequency Counter Module 1 Input delivers a robust, accurate, and reliable solution for industrial frequency measurement. Its precise specifications, wide input range, rugged design, and real-time monitoring capabilities ensure operational efficiency and system stability. Proper installation, configuration, and maintenance allow industrial operators to maximize its performance, making it an essential component for industrial automation and control applications.

Reviews

There are no reviews yet.