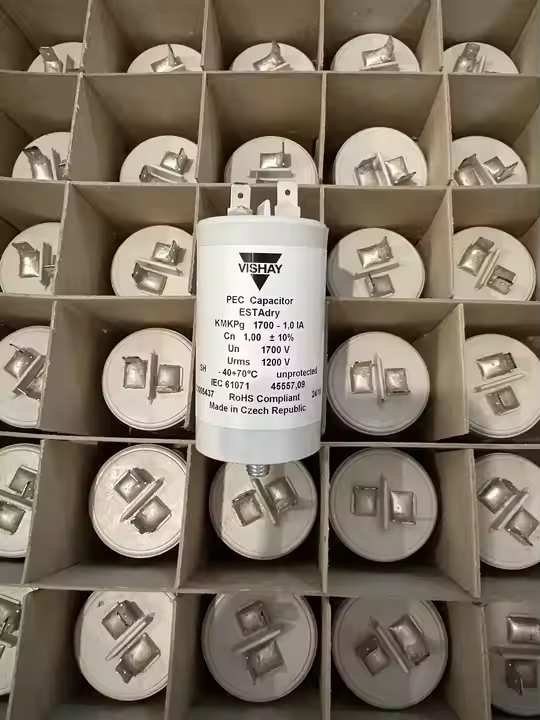

VISHAY KMKPg1700-1.0IA Capacitor: A Complete High-Reliability Industrial Power Solution

Industrial power systems continue to evolve rapidly, and engineers constantly search for components that deliver stronger performance, longer lifespan, and higher reliability. Although many capacitor models attempt to satisfy these requirements, the VISHAY KMKPg1700-1.0IA stands out because it offers exceptional stability in harsh, high-demand environments. Moreover, it supports modern energy-conversion technologies, and it also improves system efficiency across a wide range of industrial applications. Because industries increasingly depend on clean, stable, and predictable electrical performance, this capacitor becomes a crucial part of many advanced designs.

To help engineers, integrators, and technical buyers understand the capabilities of this component, this article provides an extremely detailed overview of the KMKPg1700-1.0IA. Additionally, it explains how the capacitor improves performance, why it eliminates common reliability issues, and how users can integrate it effectively into industrial systems. Therefore, readers gain a complete and practical understanding that supports real-world decision-making.

1. Overview of the VISHAY KMKPg1700-1.0IA

The KMKPg1700-1.0IA belongs to VISHAY’s high-performance polypropylene film capacitor family. Although the market offers many film capacitors, this version delivers unusually strong electrical and thermal characteristics. Because of its advanced construction, it ensures precise behavior during rapid switching cycles, and it maintains full performance even when temperatures fluctuate dramatically. Additionally, its dry-type structure eliminates leakage concerns, so engineers enjoy safer long-term operation.

Furthermore, this capacitor fits easily into compact system designs since its mechanical structure reduces installation space. Therefore, designers gain more freedom to arrange power modules, controllers, converters, and filters.

2. Construction Features That Strengthen Performance

Although the capacitor appears simple from the outside, its internal structure determines its reliability. The KMKPg1700-1.0IA uses a metallized polypropylene film that offers excellent dielectric strength. Because this material minimizes energy loss, the capacitor delivers high efficiency across a wide frequency range. Moreover, the film tolerates continuous thermal cycling without degrading, so engineers gain stronger lifetime performance than many conventional alternatives.

Additionally, the capacitor uses a dry non-impregnated design. This approach improves safety, since the component eliminates the possibility of liquid leakage. Because of this, the device becomes suitable for sensitive environments such as automation cabinets or control rooms where leakage could damage equipment.

Furthermore, VISHAY’s internal winding structure reduces inductance and ESR. Therefore, the capacitor moves energy more efficiently through the circuit and prevents excessive heat generation during operation. Since lower internal temperature directly increases lifespan, this design advantage provides long-term value for industrial users.

3. Electrical Characteristics That Improve System Stability

Although many capacitors support basic filtering, not all maintain stable performance under severe loads. The KMKPg1700-1.0IA does, and it consistently delivers clean electrical behavior even when feeders, inverters, or drives produce noise or harmonic distortion. Because the component stabilizes voltage variations, the entire electrical system performs more smoothly.

3.1 Capacitance Stability Across Temperature

The capacitor maintains near-constant capacitance even when temperatures shift significantly. Since industrial environments often experience fluctuating thermal conditions, this consistency helps protect equipment from irregular power flow. Moreover, stable capacitance improves control accuracy for automation devices.

3.2 Low ESR That Reduces Energy Loss

As ESR decreases, the capacitor produces less internal heat. Because heating causes early failure in many components, the low-ESR design directly improves reliability. Additionally, lower ESR enhances converter and inverter efficiency, so power systems waste less energy.

3.3 High Ripple-Current Handling Capability

Modern power electronics operate with high switching frequencies. Although many capacitor models struggle to manage high ripple currents, the KMKPg1700-1.0IA handles them with ease. Because it tolerates ripple without excess heating, the capacitor ensures clean DC bus behavior in demanding systems.

4. Thermal Performance That Supports Heavy-Duty Systems

Although electrical strength is crucial, thermal performance determines how well a capacitor survives under real industrial stress. The KMKPg1700-1.0IA offers excellent temperature management.

4.1 Strong Heat Dissipation

The internal design allows heat to distribute evenly instead of concentrating on specific points. Therefore, the capacitor resists thermal breakdown during long-term continuous operation.

4.2 Stable Behavior During Repeated Thermal Cycling

Industrial systems frequently start and stop throughout the day. Because repeated warming and cooling can damage weaker materials, many capacitors lose reliability over time. However, the polypropylene film inside the KMKPg1700-1.0IA tolerates this expansion and contraction easily, so the component retains its full performance longer.

4.3 Wide Operating Temperature Range

The capacitor remains stable across broad temperature conditions, so engineers integrate it into device enclosures, control cabinets, outdoor stations, or high-heat industrial zones. Because the component handles these difficult environments, system designers gain more flexibility.

5. Ideal Applications for the VISHAY KMKPg1700-1.0IA

Although this capacitor supports almost any high-performance industrial system, some applications benefit especially strongly.

5.1 DC-Link Circuits in Power Converters

Solar inverters, UPS systems, motor drives, and energy-conversion units use DC-link capacitors to stabilize internal buses. Because the KMKPg1700-1.0IA offers low ESR and high ripple-current tolerance, it improves conversion efficiency. Moreover, stable DC-link behavior extends the lifespan of surrounding modules.

5.2 Industrial Motor Drives and Automation Lines

Variable-frequency drives introduce electrical noise during rapid switching. Because the KMKPg1700-1.0IA smooths the waveform effectively, it improves motor stability and enhances control accuracy. Therefore, automation lines operate more consistently, and machines experience less vibration and fewer performance fluctuations.

5.3 Harmonic Filters and Power-Quality Equipment

Factories that operate heavy machinery frequently struggle with harmonic distortion. However, this capacitor supports filter networks by absorbing unwanted noise. Since better filtering improves overall power quality, production systems operate more efficiently.

5.4 Renewable-Energy Conversion Systems

Wind and solar energy platforms require high-performance capacitors because environmental conditions change rapidly. Because this model remains stable under thermal and electrical stress, renewable-energy equipment gains higher reliability and longer service life.

5.5 High-Voltage Industrial Equipment

Large rectifiers, high-voltage supplies, and industrial measurement systems depend on stable filtering. Since the KMKPg1700-1.0IA supports these needs easily, it becomes a strong choice for advanced technical installations.

6. Engineering Advantages That Reduce Operational Costs

Although initial component selection focuses on electrical specifications, long-term operational cost often matters more. Because the KMKPg1700-1.0IA offers excellent durability, it significantly reduces lifecycle expenses.

6.1 Extended Component Lifespan

Thermal and electrical stability naturally extend the capacitor’s life. Therefore, users replace components less frequently. Since replacement downtime affects production efficiency, longer lifespan directly increases profitability.

6.2 Improved System Efficiency

Low ESR and stable capacitance improve power-conversion efficiency. Because industrial systems consume large amounts of electricity, even small improvements reduce annual operating costs.

6.3 Reduced Maintenance Requirements

The capacitor’s dry-type structure simplifies maintenance routines. Since it requires only visual inspections, maintenance teams spend less time checking equipment. Moreover, the component rarely fails under normal conditions, so factories avoid unexpected shutdowns.

7. Installation Guidelines That Improve Safety and Performance

Although the capacitor performs well even under general installation methods, engineers gain stronger results when they follow specific guidelines.

7.1 Provide Adequate Ventilation

Good airflow ensures lower temperatures, so the capacitor maintains maximum lifespan. Because heat accelerates degradation, proper ventilation becomes a critical factor in long-term reliability.

7.2 Match Capacitor Ratings With System Ripple Conditions

Although the KMKPg1700-1.0IA tolerates heavy ripple, engineers still improve performance by evaluating real internal currents. Therefore, correct rating selection ensures reliable performance even during peak loads.

7.3 Maintain Clean Electrical Connections

Clean terminals reduce contact resistance and prevent overheating. Since many industrial cabinets accumulate dust, periodic cleaning protects electrical stability.

8. Maintenance Practices That Enhance Reliability

Although the capacitor requires minimal maintenance, users can still follow several beneficial practices.

8.1 Conduct Regular Visual Inspections

Engineers detect external issues easily through periodic inspection. Because visual checks take only a few seconds, they offer significant protective value.

8.2 Monitor System Temperature Trends

Thermal changes inside the equipment sometimes indicate airflow restrictions. Because early detection prevents failures, engineers benefit from continuous monitoring.

8.3 Evaluate Ripple Behavior During Upgrades

When users upgrade motor drives, converters, or other power modules, ripple characteristics may change. Therefore, periodic evaluation ensures the capacitor continues to operate under safe conditions.

9. Long-Term Benefits for Power-Electronics Designers

The KMKPg1700-1.0IA not only improves system stability but also simplifies engineering decisions.

9.1 Consistent Performance Across Environments

Because the capacitor maintains stable electrical behavior even when temperatures and loads fluctuate, designers enjoy predictable system performance.

9.2 Strong Reliability That Reduces Risk

Industrial systems cannot tolerate unexpected failures. Because the KMKPg1700-1.0IA demonstrates remarkable endurance, designers reduce risk and protect long-term operations.

9.3 Compatibility With Modern High-Frequency Designs

Modern electronic systems operate at higher switching frequencies than older equipment. Since this capacitor responds quickly and efficiently, it supports next-generation industrial platforms.

10. Summary: Why the VISHAY KMKPg1700-1.0IA Stands Out

The VISHAY KMKPg1700-1.0IA offers an outstanding combination of thermal strength, low ESR, high stability, and long lifespan. Although many capacitor models attempt to compete, few deliver the same level of reliability in such a wide range of industrial environments. Moreover, the component enhances system efficiency and reduces maintenance requirements. Therefore, engineers choose it for applications involving motor drives, power converters, industrial filters, renewable-energy systems, and advanced automation lines.

Because clean power, stable performance, and long equipment lifespan remain essential for modern industries, the KMKPg1700-1.0IA continues to serve as a reliable, future-ready energy-storage component that strengthens every electrical system it supports.

Reviews

There are no reviews yet.