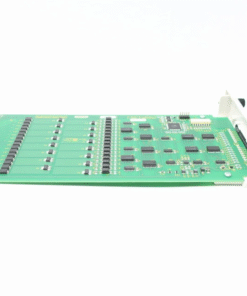

ABB IMDSM04 Pulse Input Module Technical Overview

The ABB IMDSM04 Pulse Input Module strengthens advanced automation systems through accurate pulse measurement, fast counting performance, and stable signal conditioning. Because the module handles up to eight independent pulse channels, engineering teams gain precise monitoring capability for flowmeters, tachometers, counters, and other devices that rely on pulse-based feedback. Furthermore, the IMDSM04 ensures dependable real-time visibility so that process decisions remain accurate, efficient, and fully synchronized with operational demands.

General Design and Functional Concept

The IMDSM04 functions as an eight-channel pulse input module that measures frequency, totalization, and event-based digital pulses across a broad range of industrial applications. Because the module interprets pulses with strong noise immunity and high counting accuracy, system integrators deploy it easily within ABB DCS architectures. Every channel processes signals independently, so multiple devices operate simultaneously without interference.

In addition, the module supports diverse pulse formats—such as dry-contact pulses, open-collector outputs, NAMUR signals, and TTL-level pulses. This design increases application flexibility and reduces the need for external converters or specialized input hardware. As a result, plants simplify hardware selection and streamline long-term maintenance planning.

Electrical Specifications and Input Capabilities

The IMDSM04 supports wide input-voltage tolerances so that field devices with varying outputs integrate smoothly. Its internal circuitry stabilizes fluctuating signals, and it applies strict threshold criteria to guarantee accurate pulse detection. Because the electrical design filters jitter, noise spikes, and interference from adjacent equipment, every recorded pulse reflects a valid physical event.

Key parameters include:

Number of channels: 8 isolated pulse inputs

Supported signal types: dry-contact, transistor, magnetic pickup, NAMUR, TTL

Input voltage range: broad acceptance for industrial sensor compatibility

Maximum pulse frequency: optimized for high-speed counting applications

Input impedance: engineered to maintain pulse shape integrity across long cable runs

Isolation: strong channel-to-channel and channel-to-system isolation

Because the IMDSM04 ensures clean electrical boundaries, the module operates without drifting, miscounting, or interpreting false transitions.

High-Speed Counting Performance

Many industrial devices rely on fast pulse sequences, and the IMDSM04 handles these demanding requirements effortlessly. The module collects high-frequency pulses with precise timing resolution, ensuring accurate frequency and totalization calculations. As processes accelerate, the module continues to capture every transition so that the DCS receives complete and reliable data.

Applications such as flow measurement, turbine rotation monitoring, conveyor tracking, and packaging equipment rely heavily on fast pulse detection. Because the IMDSM04 maintains real-time responsiveness, automation systems stay synchronized with machine motion and process speed. Consequently, engineers improve product consistency and optimize control-loop efficiency.

Signal Conditioning and Noise Immunity

Industrial facilities generate electrical noise from motors, inverters, relays, and switching equipment. The IMDSM04 solves this challenge through advanced signal conditioning. Its built-in filters eliminate unwanted disturbances, smooth pulse edges, and enforce stable logic thresholds. Therefore, external environmental conditions do not degrade measurement quality.

The module manages:

high-frequency electromagnetic interference

voltage transients

contact bounce from mechanical switches

long-distance cable noise

ground-loop irregularities

Because the IMDSM04 stabilizes every input before handing it to the controller, its output delivers consistent clarity. As a result, troubleshooting becomes easier, and long-term environmental changes cause fewer measurement issues.

Real-Time Diagnostics and LED Indicators

Each of the eight channels includes clear LED indicators that display pulse activity during commissioning and operation. These LEDs help technicians verify wiring, confirm pulse transmission, and identify signal irregularities immediately. Because the indicators react instantly to input transitions, engineers check circuits without additional tools.

Furthermore, the module communicates diagnostic data to ABB DCS systems, including abnormal pulse frequency, wiring quality alerts, and device-level error conditions. Because this information improves visibility, maintenance teams locate issues quickly and maintain high system uptime.

Mechanical Structure and Rugged Construction

The IMDSM04 uses a compact and durable housing built for long-term industrial deployment. The module resists high temperatures, shock, vibration, and humidity variations that typically challenge electronic assemblies. ABB’s robust mechanical engineering ensures continued reliability even when installed near rotating machinery, high-energy electrical systems, or outdoor enclosures.

The front-panel layout offers clear labeling, channel numbering, and logical arrangement for convenient wiring. Each terminal connection locks firmly, so wiring remains stable during vibration or thermal expansion cycles. Consequently, the IMDSM04 reduces wiring failures and lowers long-term maintenance requirements.

Installation and Rack Compatibility

The IMDSM04 fits directly into ABB system racks used across Symphony, Harmony, and Bailey process-control architectures. The modular format allows fast installation, and technicians slide the unit into the rack without altering existing control code. Because the module synchronizes easily with ABB system scan cycles, it integrates seamlessly into both new and legacy control environments.

This backward-compatible design supports:

mixed-generation ABB I/O systems

incremental plant upgrades

modernization projects requiring minimal downtime

Moreover, when facilities expand I/O capacity, the IMDSM04 adds additional pulse measurement capability without modifying cabinet dimensions.

Environmental and Operating Conditions

The IMDSM04 performs reliably in demanding industrial environments because ABB designs the module with wide environmental tolerance:

strong EMI shielding

resistance to dust and airborne contamination

reliable operation across extended temperature ranges

vibration-resistant build quality

long-term durability tested under continuous operation

Therefore, industries such as power generation, petrochemical processing, material handling, water treatment, steel manufacturing, food processing, and heavy machinery benefit from stable pulse monitoring.

Application Areas

Because the IMDSM04 supports universal pulse inputs, it applies across many industrial systems:

Flow monitoring: turbine flowmeters, magnetic pickups, and positive displacement meters

Speed measurement: conveyor encoders, turbine wheels, and high-speed rotating shafts

Counting applications: packaging cycles, production counts, and batching operations

Energy measurement: pulse outputs from power meters and utility monitoring instruments

Machine motion control: indexers, timing wheels, and position-tracking mechanisms

The module’s flexibility shortens engineering time and simplifies system standardization.

Operational Value and Long-Term Benefits

The IMDSM04 strengthens plant automation by ensuring accurate pulse measurement, high-frequency detection, and reliable long-term operation. Because the module supports universal pulse formats and strong noise immunity, engineers reduce configuration complexity and avoid device-compatibility problems.

Over time, its durability and stability reduce maintenance cost, minimize signal-quality issues, and improve the overall reliability of critical control loops. Consequently, the IMDSM04 becomes a core building block for process optimization, energy tracking, and equipment-performance improvement.

Conclusion

The ABB IMDSM04 Pulse Input Module stands out as a versatile and high-performance solution for pulse-based measurement across modern industrial systems. Because the module manages eight inputs with strong isolation, wide voltage capability, noise-proof filtering, and high-speed counting accuracy, it supports precise process monitoring and seamless integration within ABB DCS platforms. Therefore, the IMDSM04 offers an ideal combination of performance, flexibility, and engineering efficiency for long-term industrial automation.

Reviews

There are no reviews yet.