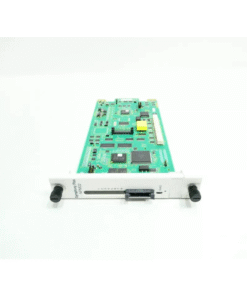

ABB IMDSI22 Universal Digital Input Module Technical Overview

The ABB IMDSI22 Universal Digital Input Module strengthens modern automation systems through accurate signal processing, stable electrical performance, and versatile field-device compatibility. Because the module interprets digital signals quickly and reliably, engineers gain precise system visibility across demanding industrial environments. Moreover, the IMDSI22 improves operational efficiency, enhances diagnostic clarity, and supports long-term system reliability within ABB’s DCS architecture. Therefore, plants achieve smoother workflows, faster troubleshooting, and consistent system uptime.

Overall Design Concept

The IMDSI22 functions as a universal digital input module, and it handles diverse input types across multiple voltage ranges. This design gives integrators wide flexibility when building or upgrading control systems. Because the module accepts mixed digital devices, such as limit switches, proximity sensors, push-button panels, and interlock signals, system architects streamline panel design and reduce hardware fragmentation. As a result, facilities simplify expansion, maintenance, and long-term upgrades.

The module incorporates a rugged mechanical architecture that withstands vibration, shock, EMI exposure, temperature variation, and dust intrusion. ABB uses industrial-grade components to ensure consistent performance throughout continuous operation. Consequently, the IMDSI22 delivers stable signal interpretation even when deployed in harsh or remote environments.

Electrical Specifications and Input Characteristics

The IMDSI22 supports multiple digital input voltage levels, allowing the module to accommodate a wide range of field-device electrical standards. Each channel follows clear threshold logic, so ON/OFF states transition smoothly and accurately. Because every signal follows strict electrical boundaries, the controller receives reliable data at all times.

In addition, ABB optimizes the module’s input impedance so that long cable runs, inductive loads, and environmental disturbances do not distort signal integrity. The IMDSI22 processes rapid switching patterns without delay or drift, and it ensures that the control system always interprets valid changes in real time.

The module incorporates per-channel isolation, and this isolation protects the controller from field faults, line disturbances, wiring errors, and ground-loop interference. As a result, system designers maintain strong electrical separation between sensitive internal electronics and unpredictable field conditions.

High-Speed Signal Processing

The IMDSI22 supports rapid input scanning, and every channel communicates state transitions without delay. Because the module synchronizes smoothly with ABB system scan cycles, time-critical applications such as machine sequencing, interlocking logic, and fast-response safety functions operate reliably.

In high-speed automated machinery, digital feedback quality directly influences stability. The IMDSI22 maintains clean digital transitions, so the controller receives continuous, interruption-free information. This performance strengthens throughput, quality consistency, and machine safety across diverse production environments.

Noise Filtering and Electrical Protection

Industrial environments introduce electrical noise from motors, inverters, relays, solenoids, and high-frequency equipment. The IMDSI22 solves this challenge through advanced noise-filtering architecture. The internal filtering circuit eliminates transient spikes, false transitions, and electrical interference. Therefore, the module interprets only valid logic states, even when noise amplitudes fluctuate during peak load cycles.

The module includes surge protection, reverse-polarity resistance, transient suppression, and robust grounding paths. Because the IMDSI22 handles these challenges internally, field wiring becomes less sensitive to environmental conditions. As a result, installations become more reliable, maintenance becomes more predictable, and long-term equipment life increases.

Diagnostic Indicators and System Feedback

Each digital input channel includes real-time LED indicators that display ON/OFF state clearly to technicians. These indicators speed up commissioning, troubleshooting, and loop checking because every channel shows transparent diagnostic information immediately.

The module communicates system-level diagnostic details to ABB controllers. This data includes channel-activity status, wiring-quality monitoring, abnormal-state detection, and potential failure prediction. Because the controller receives continuous feedback, engineers identify issues early and take action before system performance suffers.

Mechanical Design, Wiring, and Installation

The IMDSI22 follows ABB’s modular installation format, and it fits smoothly into standard rack assemblies. The module uses high-strength materials that resist heat, vibration, and physical impact. Consequently, the device maintains firm operation even during demanding production processes.

The terminal layout supports organized wiring. Each point includes clear numbering, durable labeling, and secure locking positions that maintain stable electrical contact over long operating periods. Because the wiring architecture favors clarity, technicians reduce installation time and avoid wiring mistakes during commissioning.

Furthermore, the compact physical footprint saves panel space, and integrators scale I/O density without enlarging cabinet size. This advantage becomes especially important during system retrofits or high-density machine upgrades.

System Integration and Compatibility

The IMDSI22 integrates seamlessly with ABB Symphony, ABB Bailey, and other compatible ABB DCS platforms. Because the module follows established communication protocols and rack architecture, engineers deploy new modules without redesigning control logic or rewriting complex system layers.

The module synchronizes cleanly with controller scan cycles, and it ensures consistent timing across all digital input channels. This consistency helps maintain high-accuracy logic execution, and it strengthens overall system coordination.

Moreover, when facilities modernize their systems, the IMDSI22 supports mixed environments that combine legacy ABB equipment with new components. Therefore, upgrade projects proceed smoothly, and users avoid unnecessary downtime or expensive hardware replacement.

Environmental and Operating Conditions

Key environmental capabilities include:

Strong tolerance to high vibration levels

Resistance to electromagnetic fields and high-noise environments

Wide operating-temperature range

Dust-resistant enclosure structure

High-durability circuit protection design

Because the IMDSI22 withstands harsh environmental factors, it performs consistently in power plants, chemical facilities, material-handling systems, oil and gas environments, water-treatment plants, and large manufacturing operations.

Application Scenarios

The IMDSI22 enhances digital feedback processing across many sectors:

Power generation: supports turbine sequencing, breaker status monitoring, and auxiliary equipment feedback.

Chemical processing: manages valve-limit signals, interlock logic, and process safety indicators.

Manufacturing automation: oversees machine-cycle triggers, conveyor sensors, and packaging equipment.

Oil and gas: processes remote sensor states in field skids, compressor stations, and pipeline control rooms.

Water and wastewater: monitors pump controls, level switches, and gate-actuator positioning.

Because the module adapts to mixed equipment and unpredictable field environments, it becomes a reliable foundation for long-term digital I/O structures.

Longevity, Reliability, and Operational Value

The IMDSI22 uses durable, industrial-grade electronics that support years of consistent operation. Internal components follow strict manufacturing standards, and they maintain performance even during continuous 24-hour operation. As a result, the module reduces maintenance load, lowers system downtime, and improves total cost of ownership.

The module also supports future expansion because ABB maintains long-term availability for compatible rack equipment and system software. Therefore, facilities modernize gradually without losing compatibility or operational stability.

Conclusion

The ABB IMDSI22 Universal Digital Input Module offers flexible voltage compatibility, high-quality signal processing, strong noise immunity, and dependable long-term operation. Because the module integrates seamlessly with ABB DCS platforms and supports mixed digital input sources, it improves system reliability and enhances engineering versatility. Therefore, the IMDSI22 becomes a valuable asset for industries that require robust digital feedback, consistent performance, and scalable control-system design.

Reviews

There are no reviews yet.