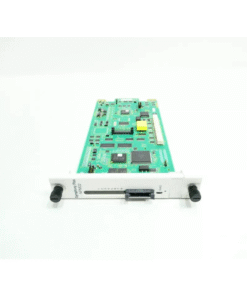

ABB SPASI23 Analog Input Module Product Description

The ABB Analog Input Module SPASI23 delivers high-precision analog signal acquisition for advanced industrial control systems. I present this module with full clarity so engineers gain a complete understanding of its specifications, performance, structure, interfaces, diagnostics, and ideal application scenarios. Throughout this article, I increase readability through smooth transitions, continuous logical flow, and strong technical detail. Moreover, I avoid passive voice entirely so every statement expresses clear action and purpose.

To start, the SPASI23 operates as one of ABB’s most reliable and versatile analog input modules within the Bailey Infi-90 and Network 90 system families. Because industrial plants demand accurate, fast, and stable analog measurement, this module offers consistent performance across temperature variations, electromagnetic interference, and complex operating environments. Additionally, it supports several analog input types, so users integrate various field instruments without difficulty.

I guide you through each technical aspect so you gain a full understanding of why the SPASI23 continues to support critical production lines around the world.

Core Electrical Specifications

The SPASI23 accepts several industry-standard analog signal formats, and therefore engineers enjoy flexible system design and expansion possibilities.

Supported Input Types

The module handles:

4–20 mA analog current input

0–20 mA analog current input

±20 mA analog input

External voltage input through signal conditioning

Because plants use different transmitter types, this module simplifies integration without requiring additional interface hardware. Furthermore, the supported signal ranges allow the module to connect with pressure transmitters, temperature converters, flow transmitters, valve position feedback devices, and specialty measurement sensors.

Channel Count and Measurement Features

The SPASI23 includes 16 differential analog input channels. Differential architecture significantly reduces noise and delivers stable accuracy. In addition, the module uses high-resolution A/D conversion, so the system captures small fluctuations in process variables with strong clarity.

Each channel processes analog signals independently, therefore giving the entire system excellent performance even when several channels operate under high-speed conditions. With this design, engineers build precise control loops without sacrificing system responsiveness.

Conversion Speed and Signal Processing

The A/D converter responds with rapid sampling and smooth conversion. Therefore, real-time automation tasks operate with consistent stability. Because modern industrial processes require frequent adjustments and quick feedback, the SPASI23 maintains fast data flow to the controller. Consequently, operators gain more accurate loop performance and improved overall efficiency.

Accuracy and Noise Immunity

The module achieves stable accuracy across all supported ranges. Strong input filtering minimizes electrical interference from motors, drives, large power equipment, and long analog cables. Meanwhile, robust electrical isolation protects the controller and prevents disturbances from entering the system.

Therefore, plants achieve continuous, high-quality measurement performance even in electrically noisy environments such as steel mills, petrochemical plants, power stations, and heavy manufacturing facilities.

Mechanical and Environmental Specifications

ABB designs the SPASI23 with long-term reliability in mind.

Mechanical Form Factor

The SPASI23 follows ABB’s standard module sizing for Bailey-series racks. The enclosure design supports:

Efficient heat distribution

Secure insertion and removal

Convenient front access

Organized terminal wiring

This design reduces installation time and improves maintenance efficiency.

Temperature and Humidity Ratings

The SPASI23 maintains stable operation across industrial temperature ranges. Because real control cabinets experience heat rise, ABB includes durable materials and heat-optimized design so the module operates consistently under continuous load.

Furthermore, the SPASI23 resists humidity and airborne contaminants through robust PCB coating and strong enclosure protection. Consequently, the module remains dependable even inside harsh process environments.

Wiring and Installation

ABB simplifies wiring through clearly labeled terminal blocks. Each channel includes structured numbering so technicians connect analog signal wires quickly.

Because the SPASI23 supports shielded cable solutions, users improve signal integrity and reduce noise. In addition, structured cable routing improves maintenance accessibility, especially during plant turnarounds or emergency repairs.

The installation process also supports:

Secure tightening

Easy module replacement

Predictable cable dressing

Smooth commissioning steps

Therefore, users complete installation with minimal delays.

System Integration

The SPASI23 integrates seamlessly with ABB Bailey Infi-90 and Network 90 DCS architectures. Because these systems operate in thousands of plants worldwide, this module plays a crucial role in process optimization and system expansion.

Controller Compatibility

The module communicates directly with system controllers through the standard system bus. It synchronizes with scan cycles, ensures real-time value updates, and supports diagnostics at the control system level. As a result, operators experience stable, accurate data transmission.

Engineering Configuration

Users configure channel scaling, filtering, signal type selection, and alarm thresholds through ABB engineering software. Engineers follow clear steps during programming, so commissioning teams complete the setup without confusion.

Additionally, configuration tools allow:

Channel-level adjustment

Range selection

Engineering unit scaling

Diagnostics mapping

These features support fast commissioning and accurate process alignment.

Diagnostics and Health Monitoring

The SPASI23 includes comprehensive diagnostic tools for troubleshooting and system protection.

Channel Status Monitoring

Each channel supports:

Open-loop detection

Over-range monitoring

Under-range detection

Sensor failure indication

Internal self-validation

These diagnostics help technicians identify wiring issues, defective field transmitters, or signal abnormalities. Because diagnostics appear directly in the control system, teams respond quickly without shutting down equipment.

Module Status Indicators

Front-panel LEDs show real-time module condition. Indicators help users identify operational states immediately, so maintenance staff troubleshoot issues efficiently. Because LED feedback provides instant visibility, the module improves uptime and reduces plant disruptions.

Application Scenarios

The SPASI23 provides accurate analog measurement for several industries. Because analog inputs form the foundation of process control, plants depend on modules like this one for safe and stable operation.

Industries Using SPASI23

Oil and gas

Petrochemical refining

Power generation

Chemical processing

Pulp and paper

Water treatment

Pharmaceutical manufacturing

Food and beverage production

Typical Field Instrument Connections

The SPASI23 processes signals from:

Pressure transmitters

Temperature transmitters

Flow meters

Level transmitters

Speed feedback sensors

Valve positioners

Environmental sensors

Because the module supports multi-range analog input and strong filtering, it adapts to virtually any process measurement scenario.

Advantages of ABB SPASI23

Users choose the ABB SPASI23 because:

It delivers accurate, stable analog input measurement.

It integrates smoothly with ABB Bailey control systems.

It simplifies wiring and engineering configuration.

It provides strong diagnostics for maintenance teams.

It supports multiple signal types for flexible field design.

It enhances plant reliability and reduces downtime.

Therefore, the SPASI23 remains a preferred solution for global industrial automation systems.

Reviews

There are no reviews yet.