Introduction

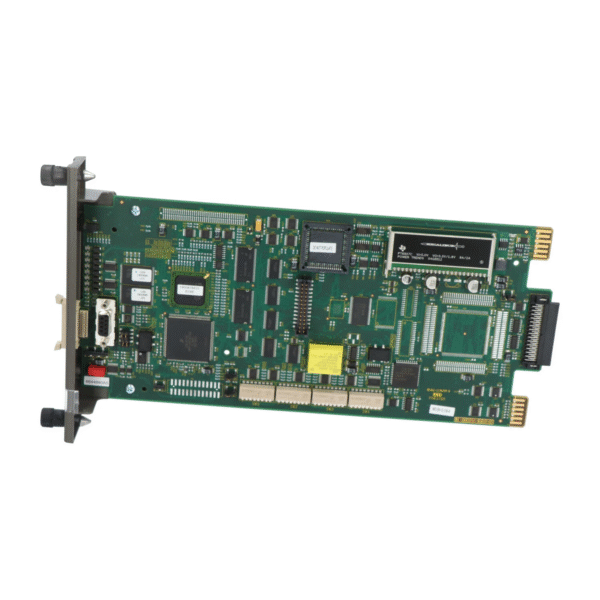

The ABB SPICI03-SCIL INFI-NET to Computer Interface strengthens industrial communication by creating a dependable and efficient data bridge between INFI-NET controllers and computer-based systems. Since modern plants rely on real-time insights, the module supports high-speed data transfer that enhances visibility, diagnostics, and operational decision-making. Moreover, the SPICI03-SCIL ensures consistent performance across complex distributed environments, and its advanced communication structure helps engineers maintain reliable network behavior even when traffic increases sharply.

As industries pursue higher accuracy and faster response times, the SPICI03-SCIL delivers streamlined workflows that simplify data exchange and strengthen information consistency. Furthermore, the module integrates tightly with ABB’s INFI-NET architecture, so users experience smooth compatibility with controllers, operator stations, engineering tools, and historical data platforms. Its internal processor organizes messages efficiently, and this efficiency helps users maintain stable operation without unnecessary delays. Therefore, the SPICI03-SCIL stands out as a vital component for industries that require uninterrupted, precise, and synchronized communication.

Core Characteristics of SPICI03-SCIL

1. Real-Time Data Exchange

The interface supports continuous real-time data transfer between INFI-NET and host computer systems. Additionally, it organizes the data flow to maintain consistent update speed, so engineers receive timely values for analysis and decision-making.

2. Enhanced Protocol Coordination

The SPICI03-SCIL communicates with INFI-NET controllers using ABB’s structured protocol framework. Consequently, the system processes commands, events, time-tagged values, and control sequences efficiently, while the SCIL-specific capabilities allow additional customization for specialized plant applications.

3. High Throughput and Optimized Processing

Since industrial loads vary, the module includes optimized algorithms that adjust message handling to maintain a stable throughput. Moreover, its internal memory buffers messages intelligently so no data drops interrupt the communication stream.

4. Diagnostic Visibility

Clear front-panel indicators reveal communication quality, network status, internal processing states, and system condition. Consequently, technicians recognize abnormal patterns quickly, and this efficiency shortens maintenance time.

5. Reliable Integration with Computer Systems

The SPICI03-SCIL interacts with host computers through ABB-defined interface functions that support engineering software, historians, SCADA systems, and advanced analytics platforms. Moreover, it ensures accurate data mapping across multiple applications.

Technical Specifications and Parameters

Electrical and Power Characteristics

Input Power Requirement: 5 VDC regulated

Typical Power Consumption: 6–8 W

Backplane Compatibility: Fully compatible with INFI-NET system backplane

Internal Protection: Circuit protection structures that stabilize voltage and prevent unwanted interference

The power design supports stable communication even during high-frequency data bursts, and its low operating consumption contributes to long-term efficiency.

Communication and Networking Parameters

Supported Network

ABB INFI-NET process control network, enabling full-duplex data communication.

Computer Communication Framework

Custom ABB communication layer designed for SCIL-based applications

Supports structured message frames for commands and process values

Enhanced processing for SCIL-specific logic applications

Supports direct interaction with engineering, historian, and industrial AI platforms

Transmission Behavior

Real-time streaming of process values, events, diagnostics, and timestamps

Frame sequencing controls ensure ordered communication

Error-checking functionality retains clean and accurate output

Intelligent buffering for high-traffic scenarios

Optimized throughput across large, distributed networks

Time Synchronization

Picks up network-wide timestamp information to ensure consistent event ordering

Delivers synchronized values to all connected software systems

The module maintains communication clarity even when multiple controllers interact with the same interface.

Environmental and Physical Specifications

Operating Environment

Operating Temperature: 0°C to +60°C

Storage Temperature: –40°C to +85°C

Relative Humidity: 5–95%, non-condensing

EMC Tolerance: Industrial-grade immunity against electrical noise

Vibration Rating: Suitable for cabinet-mounted control system environments

Physical Dimensions

Standard ABB / Bailey module form factor

Convection-cooled through rack airflow

Rack-mounted installation with secure locking edge connector

Mechanical Material Construction

Industrial-grade circuit board materials

Reinforced connectors to support long operating cycles

Protective coating on sensitive components to increase reliability in harsh environments

Internal Hardware Architecture

Processing Unit

High-reliability communication processor

Fast execution for message sequencing, filtering, and routing

SCIL-enhanced logic support

Memory Resources

Program Memory: Flash/EPROM for firmware and communication logic

Data Memory: RAM dedicated to buffering messages and error logs

Diagnostic Memory: Stores error entries, status snapshots, and internal counters

System Monitoring

Internal watchdog structure that maintains stable behavior

Monitoring circuits track voltage, temperature, and communication health

Detailed diagnostic messages available through engineering tools

Software Integration and Configuration

Configuration Tools

Fully compatible with ABB automation engineering suites

Supports SCIL-integrated data models

Enables flexible mapping of controller variables to computer applications

Data Organization

Uses advanced field-mapping functions

Supports hierarchical data structures for large process models

Maintains consistent variable naming across entire engineering environment

Event and Command Handling

Accepts computer-originated control commands

Transfers plant events with accurate timestamps

Organizes event data to support sequence-of-events and analysis tools

Firmware

Secure, service-based firmware upgrade procedure

Backward-compatible logic ensures stable system continuity

Application Scenarios

1. Power Generation Plants

The module helps centralize monitoring and supports predictive maintenance workflows. Moreover, it strengthens the link between INFI-NET controllers and high-performance computing servers that run plant diagnostics.

2. Chemical and Petrochemical Facilities

Since chemical operations demand precise timing and continuous updates, the SPICI03-SCIL supports fast process value transfer and reliable historian logging.

3. SCADA and Distributed Control Centers

The module helps SCADA stations interpret plant-wide values, event sequences, and alarms. Consequently, operators receive real-time insight across multiple production units.

4. Process Optimization and AI Integration

Advanced optimization tools rely on stable data flow. Therefore, the SPICI03-SCIL ensures that analysis engines, digital twins, and AI models process accurate information.

5. Engineering Workstations

Engineers use the interface to fine-tune control loops, analyze performance, and validate logic. Furthermore, the SCIL-enhanced structure supports complex diagnostic workflows.

Advantages of SPICI03-SCIL

1. Strong Communication Stability

Since the module organizes communication logically and filters unnecessary frames, users experience clean, uninterrupted data exchange.

2. Easy Integration

Whether connecting engineering tools, SCADA systems, or databases, the SPICI03-SCIL integrates smoothly into existing environments without additional complexity.

3. SCIL-Enhanced Functionality

The SCIL-specific capabilities offer more control, improved logic processing, and flexible data structuring that standard modules cannot provide.

4. Long-Term Operational Reliability

The durable hardware, strong diagnostics, and environmental resistance support continuous multi-year operation.

5. Efficient Handling of Large Data Structures

The interface arranges data for large, distributed networks and keeps everything synchronized, even during peak demand.

Conclusion

The ABB SPICI03-SCIL INFI-NET to Computer Interface delivers the communication stability, processing performance, and SCIL-enhanced capabilities needed for advanced industrial applications. Its real-time data transfer, clear diagnostics, reliable environmental tolerance, and seamless computer integration make it a critical component across power, chemical, manufacturing, and SCADA-based environments. Moreover, its scalable design and strong communication integrity ensure long-term operational continuity, supporting modern demands for precision, speed, and automation intelligence.

Reviews

There are no reviews yet.