ABB INFI-NET TO COMPUTER INTERFACE INICI03 – Complete Technical Overview with Specifications

Introduction

The ABB INFI-NET to Computer Interface INICI03 transforms complex plant data into accessible, real-time information that supports advanced monitoring, analysis, and control. As modern industrial environments evolve rapidly, engineers rely on robust communication modules that bridge distributed control networks with computer-based applications. Therefore, the INICI03 delivers a powerful, stable, and scalable interface that supports the full range of INFI-NET data transfers with exceptional accuracy. Moreover, its architecture enhances system interoperability, and its optimized communication algorithms maintain dependable throughput even under high-load conditions.

To ensure seamless workflow integration, the module interacts directly with a host computer while sustaining efficient command processing. Consequently, users experience rapid response, continuous data availability, strong network reliability, and simplified configuration management. Since plants demand long-term consistency, the INICI03 operates with durable hardware components, extended temperature tolerance, and well-defined diagnostic indicators that help technicians maintain peak system performance. Furthermore, the module supports deterministic communication structures that guarantee precise synchronization across distributed systems.

Core Features of INICI03

1. Real-Time INFI-NET to Computer Communication

The module exchanges continuous streams of process data with computer systems through a high-integrity INFI-NET interface. Additionally, it supports high-speed data acquisition loops that ensure uninterrupted updating of operational data.

2. Robust Protocol Compatibility

The INICI03 integrates seamlessly into ABB INFI-NET architecture. Moreover, its communication protocol supports message sequencing, error checking, time-tagged data transfers, and structured data packaging that improve operational clarity.

3. High Data Throughput

Engineers who require rapid analytics benefit from the module’s optimized bandwidth design. Furthermore, it prioritizes essential data frames, and this prioritization maintains stable transmission under heavy system demand.

4. Strong System Diagnostics

Onboard diagnostic indicators offer immediate visibility into network status, communication quality, and module health. Additionally, built-in error registers and log reporting functions help technicians identify issues quickly.

5. Simple Integration with Computer Systems

Although the module interacts with complex plant networks, it maintains a straightforward interface with computers. Therefore, users integrate it easily into data servers, engineering stations, historians, analysis tools, reporting software, or HMI platforms.

Technical Specifications and Parameters

Electrical Characteristics

Power Supply: 5 VDC regulated

Power Consumption: Typically 6–8 W

Backplane Interface: INFI-NET compatible system bus

Input Signal Levels: Fully compliant with ABB communication standards

Communication Parameters

Supported Network: ABB INFI-NET

Data Transfer Mode: Continuous, real-time, error-checked

Transmission Rate: Optimized for high throughput across distributed systems

Frame Handling: Supports message buffering and prioritized sequencing

Computer Interface Type: Designed for host computer integration with standard data communication libraries

Environmental Conditions

Operating Temperature: 0°C to +60°C

Storage Temperature: –40°C to +85°C

Humidity: 5–95% non-condensing

Vibration/Noise Rating: Industrial grade, suitable for control cabinet installation

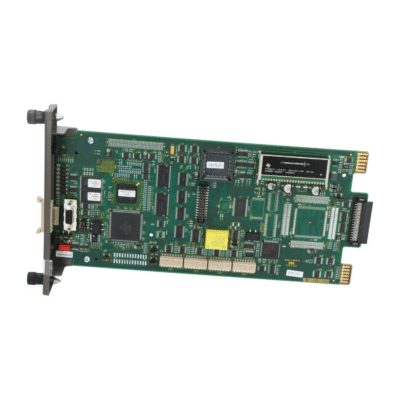

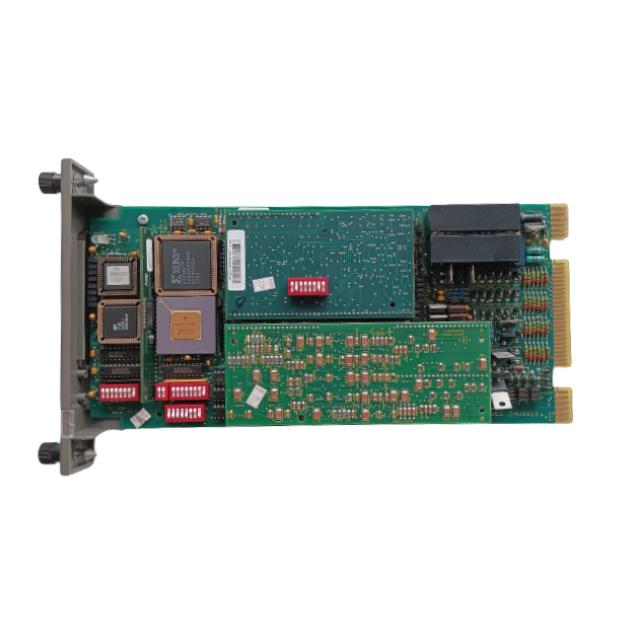

Physical Characteristics

Module Format: Standard Bailey/ABB INFI-NET module form factor

Cooling Method: Convection through chassis airflow

Mounting: Slot-based installation in INFI-NET mounting rack

Processing and Memory Structure

Processor: High-reliability embedded processor optimized for communication tasks

Memory Capacity:

Program Memory: EPROM/Flash depending on revision

Data Memory: RAM dedicated to message handling

Error Checking: CRC and sequence validation

Software & Configuration

Configuration Tools: Compatible with ABB engineering & diagnostic software

Data Mapping: Supports structured mapping for user applications

Time Handling: Network-wide timestamp passing for synchronized events

Firmware: Upgradeable through standard service procedures

Applications

The INICI03 plays a central role in environments where industrial plants require real-time data interaction between distributed controllers and higher-level computer systems. Consequently, users deploy the module in:

Power plants using INFI-NET-based distributed control systems

Chemical production lines requiring centralized data analytics

Process industries needing secure communication between controllers and servers

Historical data logging and trend management systems

Engineering workstations for diagnostics and tuning

SCADA communication gateways

Each of these applications benefits from the module’s strong reliability, consistent performance, and seamless communication flow.

Advantages of Using INICI03

1. Enhanced System Visibility

The module improves situational awareness by delivering timely data to supervisory computers. Moreover, rapid updates support predictive analysis, fault detection, and operational optimization.

2. Seamless Scalability

As plant requirements grow, the INICI03 integrates easily with expanded INFI-NET networks and advanced host software systems. Therefore, engineers scale communication networks without restructuring.

3. Improved Reliability

The communication integrity, strong environmental tolerance, and well-defined diagnostics ensure minimal downtime. Furthermore, technicians track module health continuously and resolve issues quickly.

4. Long-Term Support Compatibility

Since ABB designs the INICI03 for long-term integration within the INFI-NET platform, users benefit from consistent performance even across generational upgrades.

5. High-Efficiency Data Processing

The module arranges communication frames intelligently and maintains fast processing under high-load conditions. Consequently, industrial computers receive clean, structured, and timely data.

Conclusion

The ABB INICI03 INFI-NET to Computer Interface stands as a vital component for plants requiring high-performance communication between distributed controllers and computer systems. Its technical strength, extensive compatibility, and efficient data transfer capability ensure reliable integration across modern industrial automation infrastructures. Furthermore, its engineering precision supports long-term stability, advanced process monitoring, and improved operational intelligence.

Reviews

There are no reviews yet.