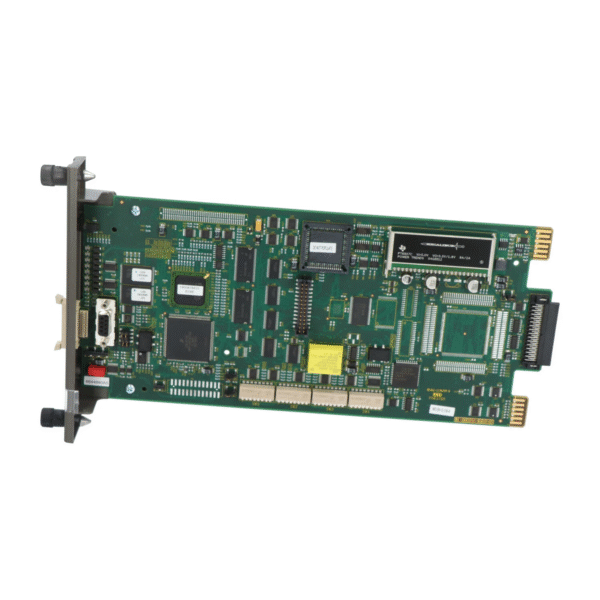

The ABB SPSEM11 Sequence of Events Master Module supports advanced event tracking across ABB Bailey automation systems. Since modern industrial applications rely on precise transitions and accurate chronological reporting, the SPSEM11 strengthens high-integrity monitoring and ensures that every event enters the system with exceptional clarity. As industries continue to pursue higher reliability, faster diagnostics, and smarter analysis, the SPSEM11 creates an efficient pathway from raw field signals to actionable engineering decisions.

To begin, the SPSEM11 uses a high-precision internal timing engine that captures microsecond-level transitions. Consequently, users interpret event sequences with unmatched accuracy. Since timestamps influence cause-and-effect analysis, alarm diagnosis, and system audits, precise timing becomes essential for stable industrial operations. Moreover, the SPSEM11 eliminates timing ambiguities and ensures every signal change flows into the system in a well-organized structure.

Furthermore, ABB designs the SPSEM11 as the master coordination module for the SOE subsystem. Therefore, it collects data from distributed SOE input modules, processes every state change, and arranges transitions into a unified event list. Because this architecture centralizes information, engineers study system behavior more quickly and more confidently, allowing downtime reduction and improved decision-making across the plant.

Additionally, the SPSEM11 integrates smoothly into ABB Bailey INFI-90 and compatible control networks. It communicates across high-speed backplane buses, interacts naturally with existing controllers, and operates without interfering with other system modules. Consequently, system expansion becomes significantly easier, and engineers add new event-monitoring capabilities without complex redesign.

1. Key Functional Capabilities of SPSEM11

The ABB SPSEM11 includes a wide collection of features that support event recording, timing accuracy, and intelligent diagnostics.

1.1 High-Resolution Event Timestamping

The SPSEM11 uses a finely tuned internal clock to capture events at extremely small time intervals. Therefore, engineers track sub-millisecond changes, even when dozens of transitions occur quickly. Since time precision shapes system interpretation, such accuracy improves both historical analysis and real-time decision support.

1.2 Central Event Management

As the SOE master module, the SPSEM11 gathers data from event input modules and arranges these signals into a well-defined chronological order. Consequently, the control system maintains clear, organized, dependable event lists that support detailed investigations.

1.3 Synchronization with System Clocks

The module synchronizes with plant-wide timing references through established ABB timing protocols. Moreover, this synchronization keeps every event aligned with the broader control network, ensuring accurate coordination across distributed system locations.

1.4 Traceable and Intelligent Diagnostics

The SPSEM11 continuously communicates its health status to the control network. Through LED indicators, internal checks, and digital diagnostic reporting, operators receive immediate insights into communication quality, configuration status, and module performance. Consequently, maintenance teams detect issues early and prevent operational disturbances.

1.5 High-Speed Communication

Through its ABB backplane bus interface, the module exchanges data at high speed with controllers, input modules, and supervisory stations. Therefore, no event data encounters bottlenecks, even during heavy signal activity.

2. Technical Specifications and Performance Parameters

Below is a structured summary of typical technical specifications for the ABB SPSEM11. These data points help engineers evaluate module suitability for their existing automation environment.

2.1 Electrical Characteristics

Power Source: Draws regulated supply from the system backplane

Input Voltage Compatibility: Matches INFI-90 system power levels

Internal Consumption: Efficient design ensures low heat output

Electrical Isolation: Protects the module from noise and ground disturbances

Surge Conditioning: Hardware filtering enhances signal integrity

2.2 Timing & Event Recording

Timestamp Resolution: Microsecond or high-precision millisecond resolution depending on system timing configuration

Event Processing Rate: Handles large bursts of transitions without data loss

Sequence Capacity: Holds extensive event histories in internal memory

Synchronization Source: Accepts timing pulses from supervisory timing modules

Event Filtering: Supports intelligent event conditioning to remove noise

2.3 Interface & Communication

Backplane Port: Connects through ABB Bailey rack communication bus

System Compatibility: Works with INFI-90, Network 90, and associated subsystems

Response Time: Maintains rapid communication cycles for time-critical applications

Data Mapping: Shares event data with controllers, HMIs, and engineering stations

2.4 Environmental Ratings

Operating Temperature: Suitable for standard control cabinet thermal limits

Storage Conditions: Retains integrity under typical warehouse environments

Humidity Range: Tolerates controlled-humidity panel environments

Electromagnetic Immunity: Performs well even in electrically noisy industrial zones

Mechanical Strength: Rigid PCB and shock-resistant frame ensure long service life

2.5 Mechanical and Installation Details

Module Type: Plug-in card for ABB Bailey system racks

Cooling Style: Uses natural airflow inside the cabinet

Front Panel Elements: Includes indicators and access points for diagnostics

Maintenance: Supports easy module replacement without rewiring

Mounting: Inserts directly into assigned rack slots

3. Primary Industrial Application Scenarios

Because the SPSEM11 excels at capturing high-speed transitions, it fits seamlessly into demanding industrial sectors that rely on precise tracking.

3.1 Power Generation & Distribution

Power plants require ultra-accurate sequencing for turbine events, protective relay signals, and system switching. Therefore, the SPSEM11 supports safe grid operations and enhances post-event reporting.

3.2 Oil, Gas, and Petrochemical Plants

In fluid processing systems, small timing differences significantly influence safety and equipment integrity. Therefore, the SPSEM11 provides critical timing insights for shutdown sequences, alarm cascades, and rapid system transitions.

3.3 Manufacturing & Metal Processing

High-speed motors, presses, and robotic cells generate constant state changes. Since traceability matters, the SPSEM11 helps operators understand mechanical faults, workflow interruptions, and equipment synchronization.

3.4 Chemical Production

Complex process reactions often involve rapid transitions. Consequently, the SPSEM11 strengthens safety-related event analysis and improves root-cause evaluations.

3.5 Water Treatment Facilities

Regulators often require detailed historical event logs for pumps, valves, and safety systems. Therefore, the module ensures clear event timelines for compliance documentation.

4. Key Advantages of ABB SPSEM11

The SPSEM11 offers several compelling advantages that improve plant reliability and operational intelligence:

Accurate microsecond-grade timestamping

Centralized coordination for all SOE inputs

Strong diagnostics for easier troubleshooting

Fast communication with ABB controllers

Stable long-term performance in harsh conditions

Smooth integration within ABB Bailey architectures

Because these strengths work together, the SPSEM11 creates a powerful platform for event visualization, operational audits, and downtime reduction.

5. Why Engineers Choose the SPSEM11

Engineers select the ABB SPSEM11 because it consistently delivers clarity, accuracy, and transparency. Since modern plants cannot afford uncertainty in their system event history, the SPSEM11 ensures every signal transition tells a complete story. Moreover, the module elevates system insight, strengthens safety planning, and improves engineering efficiency across the entire automation landscape.

Reviews

There are no reviews yet.