The ABB BRC400 bridge controller provides advanced industrial automation because it ensures precise signal management, high-speed communication, and robust system reliability. Modern industrial environments require accurate coordination among multiple subsystems, and the BRC400 supports these needs through efficient bus management, deterministic signal distribution, and seamless integration with ABB automation platforms. Engineers rely on this controller for its compact design, flexible connectivity, and predictable performance across diverse industrial networks.

The BRC400 functions as a central hub, managing data flow between ABB I/O modules, processors, and supervisory systems. By prioritizing critical signals, maintaining low-latency communication, and ensuring high data integrity, it enhances operational stability and reduces potential downtime. Moreover, the controller simplifies system configuration, enables rapid deployment, and supports incremental upgrades without interrupting existing infrastructure.

1. Core Functional Role

The BRC400 serves as a high-speed bridge controller that coordinates communication across multiple ABB devices. It ensures deterministic data transfer, guarantees timely command execution, and preserves signal fidelity even under heavy network load. Additionally, the BRC400 enables integration between legacy equipment and modern digital modules, allowing facilities to expand or modernize their automation systems gradually.

By distributing control commands efficiently, the controller ensures that each subsystem receives precise instructions, strengthening plant-wide process control, supporting safety protocols, and optimizing overall operational efficiency.

2. Key Features

2.1 High-Speed Bus Management

The BRC400 optimizes bus communication, reduces latency, and prevents signal collision. It provides predictable data flow, which is critical for time-sensitive applications in manufacturing, chemical processing, and energy production.

2.2 Reliable Signal Integrity

The controller monitors all incoming and outgoing signals, immediately identifies errors, and maintains high signal fidelity across connected devices. This feature ensures accurate control loop operation and minimizes operational risk.

2.3 Advanced Diagnostics

Integrated diagnostic indicators and software provide real-time insight into operational status, bus activity, and system health. Maintenance teams can detect anomalies quickly, reducing downtime and improving overall efficiency.

2.4 Seamless ABB Integration

The BRC400 aligns with ABB cabinet standards and mechanical designs, enabling fast installation and replacement. It integrates effortlessly into existing and new systems, supporting gradual upgrades and modular expansion without operational disruption.

3. Technical Specifications

Operating Voltage: Compatible with ABB cabinet systems

Power Consumption: Efficient design for low heat generation

Bus Protocol Support: ABB industrial communication standards

Communication Rate: High-speed, deterministic data transfer

Environmental Tolerance: Operates within wide temperature and humidity ranges

EMC Compliance: Built-in shielding reduces electromagnetic interference

Vibration Resistance: Reinforced design withstands industrial vibrations

These specifications ensure the BRC400 operates reliably in demanding industrial environments where stability and precision are essential.

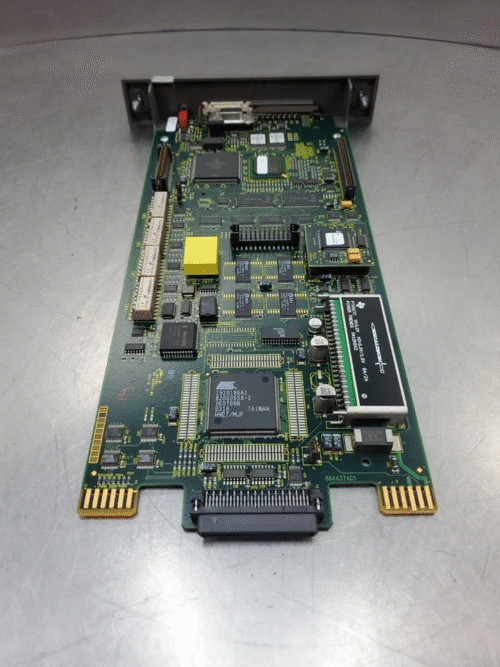

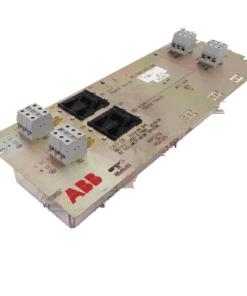

4. Mechanical Design

The BRC400 features a robust enclosure designed for ABB cabinet installations. It includes secure backplane connectors, a compact form factor, and front-panel LEDs indicating operational status, communication activity, and fault conditions. This modular design allows for easy installation, replacement, and efficient thermal management within crowded cabinets.

5. Environmental Durability

The controller maintains reliable operation in harsh industrial conditions, including temperature fluctuations, high humidity, and mechanical vibration. Advanced thermal management, shock-resistant components, and protective shielding ensure continuous, stable performance in chemical plants, power stations, manufacturing facilities, and water treatment plants.

6. Integration and Deployment

ABB designed the BRC400 for straightforward installation and integration:

Insert the controller into the designated cabinet slot.

Align and secure the backplane connector.

Connect the bus lines following ABB standards.

Verify operation using front-panel LEDs.

Configure the module via ABB system software.

This workflow ensures rapid commissioning, reliable operation, and minimal disruption to existing networks.

7. Reliability and Lifecycle Performance

ABB manufactures the BRC400 with high-quality components and advanced thermal and error-handling mechanisms. The controller delivers long-term reliability, predictable control behavior, and reduced maintenance effort. Plants benefit from continuous operation, stable system performance, and optimized industrial processes.

8. Application Scenarios

The BRC400 suits various industrial applications, including:

Manufacturing automation

Chemical and petrochemical plants

Water treatment facilities

Power generation systems

Material handling and logistics

In each scenario, the BRC400 provides precise signal coordination, reliable communication, and robust bridge control to enhance system performance and productivity.

Conclusion

The ABB BRC400 bridge controller strengthens industrial automation by offering high-speed bus coordination, signal integrity, and durable performance. Its seamless integration with ABB systems ensures reliable operation, rapid deployment, and scalable network expansion. Facilities adopt the BRC400 when they require precise, efficient, and dependable bridge control to maintain stable and optimized industrial operations.

Reviews

There are no reviews yet.