The ABB INIET800 module improves industrial communication performance because it enhances Ethernet connectivity, strengthens automation data pathways, and supports high-speed network integration across ABB control platforms. Modern industries rely on real-time insight, and the INIET800 delivers stable throughput and accurate communication timing. Furthermore, the module works smoothly inside complex distributed control architectures, and it supports system expansion without redesigning existing cabinet layouts. As data requirements continue to grow, this module keeps communication behavior predictable and ensures that operators maintain complete visibility across the entire plant structure.

The INIET800 integrates advanced networking hardware with ABB-optimized firmware. Therefore, it handles large data frames effectively, reduces jitter, and ensures continuous availability of industrial data. Because Ethernet communication forms the backbone of many automation environments, the module offers strong reinforcement for mission-critical connectivity. Additionally, engineers value its modular form factor, efficient heat management, and easy installation workflow, which together accelerate the deployment of new automation segments.

1. Role of the INIET800 in ABB Automation Systems

The INIET800 functions as a dedicated Ethernet interface module that extends high-speed network access to ABB process controllers, remote I/O clusters, and supervisory systems. The module supports robust intra-system communication, and it distributes data to various operational layers with consistent timing. Since industrial applications often involve numerous data-dependent operations, the INIET800 ensures that every subsystem communicates clearly and synchronously.

Moreover, the module supports network segmentation strategies that help operators maintain organized data flows. Complex plant environments often mix SCADA traffic, controller loops, diagnostic streams, and safety-related data. The INIET800 handles these communication branches with clear prioritization rules, and it ensures that critical packets reach their destination first. As a result, automation loops operate smoothly even during periods of elevated network activity.

2. Key Functional Characteristics

2.1 High-Speed Ethernet Connectivity

The module supports industrial-grade Ethernet protocols, and it manages data exchanges at speeds suitable for modern distributed control requirements. The communication engine inside the INIET800 delivers consistent cycle times, and it keeps jitter extremely low. Because high-precision loops require stable timing, this capability enhances plant-wide control accuracy.

2.2 Reliable Packet Handling

The INIET800 validates every packet as it flows through the system. Therefore, corrupted or incomplete data does not enter the process control environment. The module uses strong filtering, and it maintains a high level of electrical noise immunity. Because many industrial sites contain large motors, drives, welders, and power converters, this capability preserves communication clarity.

2.3 Intelligent Diagnostic Framework

LED indicators and internal software flags work together to inform engineers about module status and network health. Instant fault visibility lowers troubleshooting time and helps maintenance teams maintain continuous uptime. Additionally, diagnostic information integrates with ABB supervisory tools, giving operators a unified view across the entire network.

2.4 Seamless Integration with ABB Systems

The INIET800 fits directly into ABB I/O and control racks, and it aligns with ABB’s mechanical and electrical interface standards. Therefore, installation stays simple and repeatable regardless of the system configuration. Engineers who upgrade older systems use this module to enhance network capabilities without altering cabinet infrastructure.

3. Technical Specifications

3.1 Electrical Specifications

The INIET800 uses a power-efficient circuit layout, and it maintains stable electrical characteristics across demanding field conditions.

Operating Voltage: Typically aligned with ABB standard cabinet backplanes

Power Consumption: Low, ensuring consistent thermal behavior and long-term reliability

Isolation: Galvanic isolation between Ethernet circuits and control logic

EMC Protection: Shielded pathways reduce interference in noisy industrial environments

These specifications ensure that the module performs reliably in plants with high electromagnetic loads.

3.2 Communication Specifications

Supported Ethernet Standards: Industrial 100 Mbps full-duplex communication

Protocol Handling: Optimized for ABB automation protocols

Frame Processing: Fast handling of cyclic and acyclic data

Communication Timing: Deterministic cycle synchronization

Error Handling: Real-time frame checks and rejection of invalid traffic

These parameters allow the module to support both legacy plant networks and next-generation control systems.

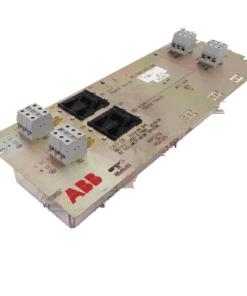

4. Mechanical and Structural Design

The INIET800 uses a robust enclosure that protects the internal circuitry from mechanical stress and environmental variation. The front-mounted LEDs display link activity, error conditions, and internal status. Additionally, the module uses secure, vibration-resistant backplane connectors that maintain reliable electrical contact during long-term operation.

The mechanical design follows ABB’s standardized cabinet form factor, which ensures consistent installation procedures across all compatible racks. Technicians can replace or upgrade the module quickly since the interface uses clear indexing marks and well-organized connector layouts.

5. Environmental Durability

Industrial facilities demand rugged modules that withstand harsh conditions. The INIET800 meets ABB’s high-reliability environmental design standards.

Temperature Range: Suitable for hot control rooms and cooler outdoor cabinets

Humidity Tolerance: High-humidity compatibility without condensation issues

Shock & Vibration: Reinforced structure ensures operational continuity

EMC Compliance: Advanced shielding maintains stable communication behavior

These attributes make the module ideal for oil refineries, chemical plants, metal processing facilities, and water treatment stations.

6. Network Architecture Integration

The INIET800 strengthens automation network architecture by functioning as a central communication gateway. It synchronizes data between controllers, aggregated I/O modules, HMIs, and supervisory platforms. Since the module supports fast Ethernet communication, every subsystem receives the data it needs with the correct timing.

Because modern automation requires clear segmentation, the INIET800 supports structured network layouts. Critical traffic, including loop feedback and control commands, flows through prioritized channels. Meanwhile, monitoring data and maintenance diagnostics follow secondary pathways. This clear separation keeps plant processes predictable regardless of network size.

7. Installation and Configuration Workflow

The module integrates smoothly into ABB cabinet systems because its installation workflow remains straightforward:

Insert the module into the ABB rack position.

Ensure the alignment keys match the enclosure markings.

Secure the module to maintain firm backplane contact.

Connect Ethernet cabling according to ABB network standards.

Verify LED indicators for link and communication readiness.

Register the module within ABB configuration software.

This quick workflow simplifies commissioning, and it allows engineers to expand network capacity rapidly.

8. Life-Cycle Performance and Maintenance

The INIET800 supports long operating life because ABB uses high-quality components and optimized thermal layout. The module handles continuous communication loads without drift in performance, and it retains signal integrity even after years of operation.

Engineers benefit from real-time monitoring because it reduces troubleshooting time and improves overall asset availability. Furthermore, ABB’s long-term product support allows industrial facilities to maintain unified system architecture without frequent hardware replacement cycles.

9. Application Scenarios

The INIET800 supports Ethernet communication across a wide range of industrial sectors:

Power generation and distribution

Petrochemical refining

Pharmaceutical manufacturing

Pulp and paper automation

Water and wastewater plants

Steel and metallurgical operations

Every environment benefits from the module’s stable communication engine and robust environmental tolerance.

10. Conclusion

The ABB INIET800 module strengthens industrial Ethernet communication by offering reliable connectivity, strong data integrity, and robust environmental durability. It integrates smoothly into ABB control architectures, and it supports modern automation requirements through deterministic communication timing and efficient packet handling. Industries adopt the INIET800 when they need a stable, scalable, and technologically advanced Ethernet interface that maintains consistent performance across entire plant environments.

Reviews

There are no reviews yet.