The ABB PHARPSCH100000 power chassis strengthens mission-critical control infrastructures because it manages system power with accuracy, redundancy, scalability, and long-term stability. Moreover, it supports ABB Bailey process controllers in environments that demand uninterrupted operation, and it ensures that every module inside the rack draws clean, balanced, and noise-free power. Consequently, plants increase availability while maintenance teams simplify diagnostics and reduce risk. Throughout this description, every section highlights how engineering choices inside the PHARPSCH100000 elevate power system integrity far beyond basic distribution frames.

1. System Purpose and Core Functional Role

The PHARPSCH100000 functions as the primary power distribution backbone inside ABB Bailey automation architectures. Although its design focuses on high-density control modules, it also organizes electrical flow so every slot receives stable power under fluctuating load conditions. Furthermore, it integrates filtering and segmentation features that prevent ripple, electrical interference, and noise spikes from spreading across the rack. Because of this, control CPUs, communication modules, I/O units, and analog interface boards operate with predictable voltage quality.

Additionally, the chassis provides secure mechanical alignment and uniform grounding, and it improves long-term reliability by minimizing thermal stress and electrical fatigue. Through these combined enhancements, plants protect their highest-value automation assets and ensure consistently smooth operations.

2. Electrical Characteristics and Power Architecture

2.1 Voltage Input Range

The PHARPSCH100000 supports regulated input levels engineered for ABB Bailey power conditioning units. Therefore, it cooperates seamlessly with industrial-grade power supplies such as PHARPSPEP and PHARPSRPC modules. Standard operating input levels typically include:

+5 VDC for logic boards

±15 VDC for analog modules

+24 VDC for auxiliary control or field interface needs

Since these voltage levels stay isolated and filtered within the chassis, sensitive electronics operate without interference from other load segments.

2.2 Current Distribution

The chassis distributes current evenly across every card slot. Moreover, it avoids load clustering because the distribution bus equalizes current draw dynamically. Therefore, the system prevents localized overheating and extends module lifespan.

2.3 Internal Protection Layers

To strengthen operational safety, the chassis incorporates:

Overcurrent interruption paths

Short-circuit isolation points

Noise-suppression filtering networks

Ground integrity monitoring segments

Because these protective elements react quickly, electrical disturbances remain contained.

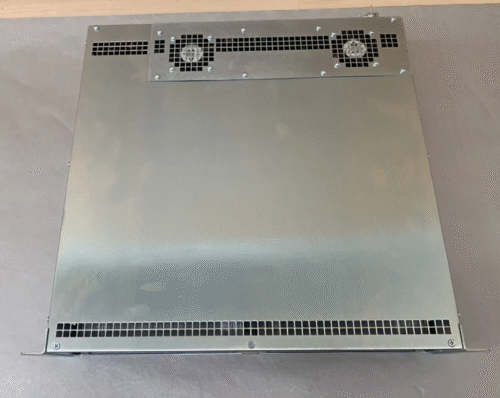

3. Mechanical Design and Durability Characteristics

3.1 Structural Materials

The PHARPSCH100000 chassis uses industrial-grade, corrosion-resistant metal alloys that maintain rigidity under vibration and thermal expansion. Consequently, it preserves alignment accuracy for all edge connectors, even when operating inside high-temperature areas or heavy-duty industrial zones.

3.2 Slot Architecture

The chassis incorporates a multi-slot, backplane-ready architecture. Each slot includes precision connectors that ensure stable module insertion and optimal signal integrity. Since the slots maintain uniform spacing, technicians insert modules quickly without risk of deformation.

3.3 Thermal Behavior

The mechanical enclosure directs airflow front-to-back, and it cooperates with cabinet ventilation systems. Because heat dissipates evenly, components operate under controlled temperature ranges, and reliability improves significantly.

4. Backplane Interface and Communication Support

The PHARPSCH100000 integrates a Bailey-compatible backplane that offers:

High-integrity signal routing

Stable low-voltage distribution tracks

Noise-isolated communication layers

Dedicated grounding frames

Although the chassis itself does not process data, it ensures that all signals flowing between modules experience minimal distortion. Therefore, controllers communicate consistently with analog boards, digital I/O units, and gateway devices.

5. Redundancy and System Stability Features

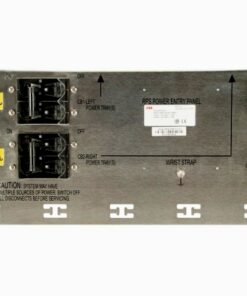

The platform emphasizes continuity of power because industrial plants cannot afford downtime. Additionally, the chassis supports dual-source redundancy when integrated with ABB redundant power modules. Through these enhancements, control loops inside Bailey systems continue functioning even during partial power disruptions.

Redundancy features include:

Dual power rail availability

Load sharing logic across distribution lines

Isolated segment protection

Fail-safe grounding channels

Because the system isolates disruptions quickly, fault conditions remain localized, and the rest of the control architecture continues operating without interruption.

6. Installation, Integration, and Field Deployment

6.1 Mounting Options

The PHARPSCH100000 mounts inside standard ABB Bailey racks. Its enclosure supports rigid fastening points that keep the chassis stable even in applications with vibration or shock movement.

6.2 Electrical Integration

Technicians connect the chassis to ABB power supply modules through secure plug-in connectors. Moreover, labeled terminals simplify wiring, reduce installation time, and prevent polarity errors.

6.3 Grounding Implementation

Ground paths flow directly through the chassis frame, and they link reliably to cabinet earth references. Because grounding quality influences signal accuracy, the chassis ensures low-impedance earth bonding.

7. Environmental and Reliability Ratings

The chassis supports operation in harsh industrial environments, and it handles demanding conditions typically found in:

Oil and gas refining

Chemical production

Power generation

Metallurgical processing

Water treatment infrastructure

Environmental capabilities include:

Wide operational temperature range

Resistance to humidity and airborne contaminants

Mechanical resilience against shock and vibration

Since ABB built this chassis for long-term stability, plants rely on it for multi-year continuous operation.

8. Maintenance Efficiency and Lifecycle Advantages

The PHARPSCH100000 also improves maintenance workflows because it offers:

Clear labeling

Front-accessible module positions

Predictable electrical behavior

Uniform slot performance

As a result, technicians troubleshoot faster, identify faulty modules more easily, and maintain stable plant uptime.

9. Technical Specifications Summary

| Parameter | Value / Description |

|---|---|

| Model | ABB PHARPSCH100000 Power Chassis |

| System Type | Bailey power distribution platform |

| Voltage Support | +5 VDC, ±15 VDC, +24 VDC |

| Slot Count | Multi-slot (Bailey-standard) |

| Backplane | ABB Bailey compatible |

| Protection Layers | Overcurrent, short-circuit isolation, noise filtering |

| Mechanical Structure | Heavy-duty industrial alloy frame |

| Cooling Method | Passive chassis airflow, cabinet-assisted ventilation |

| Grounding | Full-frame grounding integration |

| Redundancy | Dual-source capable |

| Application | High-availability ABB Bailey control systems |

10. Conclusion

The ABB PHARPSCH100000 power chassis strengthens the foundation of every Bailey automation system because it distributes clean, stable, and precisely managed power across every control module. Furthermore, it elevates reliability, enhances redundancy, and ensures predictable performance across decades of industrial operation. Therefore, plants that require uninterrupted stability view this chassis as a core infrastructure element rather than a simple mechanical frame.

Reviews

There are no reviews yet.